7 axis machines series IXN

6 axis machines series SiC , MT

5 axis machines series CCN, PWN

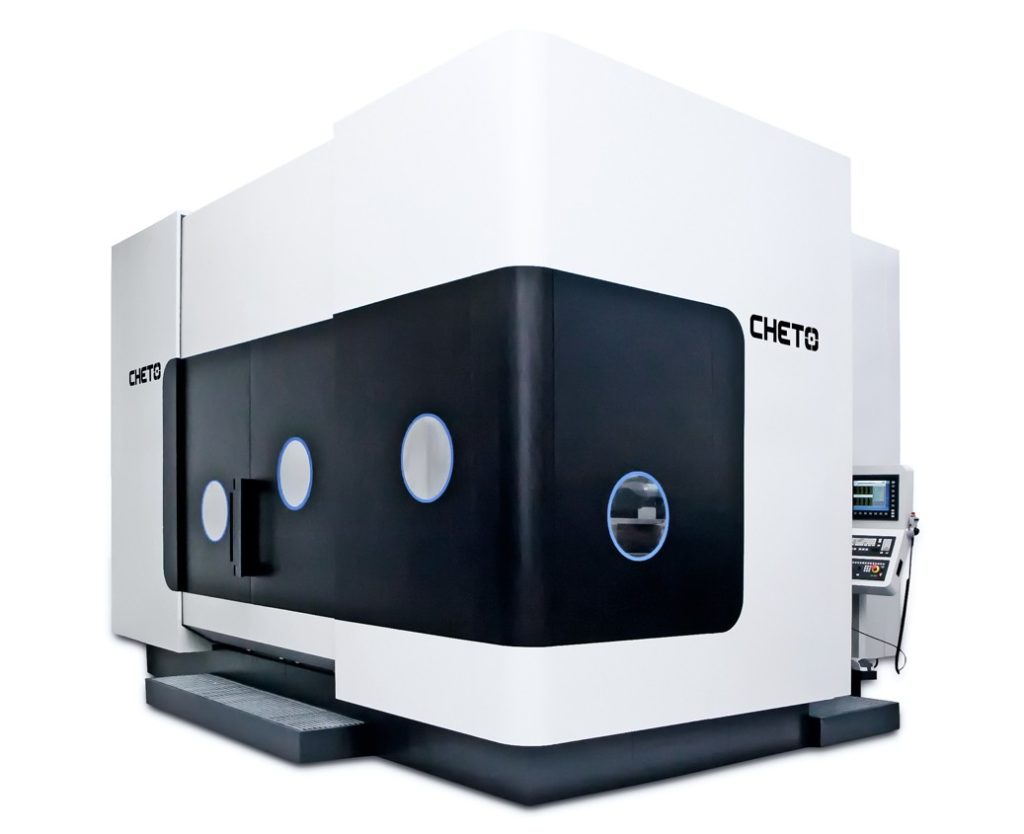

Cheto all in one

- DEEP HOLE DRILLING MACHINE

- RADIAL DRILLING MILLING MACHINE

- TAPPING MACHINE

- BORING MACHINE

7 axis machines IXN 1000 | 2000 | 3000

Standard equipment

• CNC FAGOR 8065

• Electronic handwheel

• Digital drives

• Nitrogen double counterweight

• Absolute linear encoders in axis X, Y, Z

• Absolute angular encoders in axis A, B

• Telescopic covers in all axis (except W)

• RTCP/Kinematics

• Rigid tapping

• Quick change between drilling/milling

• Coolant tank with automatic filtering

• Submerged pumps for oil recirculation

• High pressure pump 80 bar, 100 l/min |

1,160 psi, 26.5 gal/min

• Automatic chip conveyor

• Complete cover with doors, glass windows and ceiling

Optional equipment

• CNC HEIDENHAIN TNC 640

• Wise software system

• ATC up to 250 tools (up to 600 mm | 23.6 in tool length)

• ATC Gun drill up to 5 tools

• Machine prepared for automatic pallets system

• Spindle tilting +25º/-25º

• Spindle gearbox

• Y axis = 1500 mm | 59.1 in

• W axis = 2000 mm | 78.7 in

• Z1 axis = 700 mm | 27.6 in

• Exhaustion system

• Electronic probe and Laser measuring system

Technical data

| Machine model IXN | 1000 | 2000 | 3000 | |||

| CNC Axis | ||||||

| W drilling one stroke | 1630 mm | 64.2 in | 1630 mm | 64.2 in | 1630 mm | 64.2 in |

| X longitudinal travel | 1000 mm | 39.4 in | 2000 mm | 78.7 in | 3000 mm | 118.1 in |

| Y vertical travel | 1000 mm | 39.4 in | 1200 mm | 47.2 in | 1200 mm | 47.2 in |

| Z cross travel | 800 mm | 31.5 in | 800 mm | 31.5 in | 800 mm | 31.5 in |

| B table rotation | 360,000 | 360,000 | 360,000 | |||

| A tilting rotation | +25º/-15º | +25º/-15º | +25º/-15º | |||

| Drilling capacity | ||||||

| Max. drilling stroke W+Z | 1630+800 mm | 64.2+31.5 in | 1630+800 mm | 64.2+31.5 in | 1630+800 mm | 64.2+31.5 in |

| Drilling capacity | ø5-40 mm | ø0.2-1.58 in | ø5-40 mm | ø0.2-1.58 in | ø5-40 mm | ø0.2-1.58 in |

| Milling capacity | ||||||

| Milling | 300 cm3/min | 18.3 in3/min | 400 cm3/min | 24.4 in3/min | 500 cm3/min | 30.5 in3/min |

| Rigid tapping | M 30 | M32 | M34 | |||

| Helical threading | Standard | Standard | Standard | |||

| Spindle unit | ||||||

| Spindle taper | ISO 50 | DIN 69871 | ISO 50 | DIN 69871 | ISO 50 | DIN 69871 |

| Speed | 0-4500 rpm | 0-4500 rpm | 0-4500 rpm | |||

| Power | 11/15 kW | 15/20 hp | 15/22 kW | 20/30 hp | 22/33 kW | 30/45 hp |

| Torque | 140/200 Nm | 103/148 ft-lbs | 191/287 Nm | 141/212 ft-lbs | 280/420 Nm | 207/310 ft-lbs |

| Automatic rotary table | ||||||

| Table size | 1300×1300 mm | 51.2×51.2 in | 1600×1300 mm | 63.0×51.2 in | 1800×1600 mm | 70.9×63.0 in |

| Positioning type | 360,000 | 360,000 | 360,000 | |||

| Max. load in rotation | 10 Ton | 22,047 lbs | 20 Ton | 44,093 lbs | 30 Ton | 66,139 lbs |

| Layout dimensions | ||||||

| Total weight | 25 Ton | 55,116 lbs | 28 Ton | 61,730 lbs | 34 Ton | 74,958 lbs |

| Foot print (WxL) | 7140×5760 mm | 281.1×226.8 in | 8690×6160 mm | 342.1×242.5 in | 9520×7410 mm | 374.8×291.7 in |

6 axis machines

SiC 650

Standard equipment

• CNC FAGOR 8065

• Wise software system

• Electronic handwheel

• Digital drives

• Nitrogen double counterweight

• Absolute linear encoders in axis X, Y, Z

• Absolute angular encoders in axis A, B

• RTCP/Kinematics

• Rigid tapping

• Quick change between drilling/milling

• Internal coolant tank with automatic filtering

• High pressure pump 80 bar, 100 l/min | 1,160 psi, 26.5 gal/min

• Automatic chip conveyor

• Complete cover with glass windows and ceiling

• Internal ATC 16 tools (up to 400 mm | 15.8 in tool length)

Optional equipment

• CNC HEIDENHAIN TNC 640

• ATC up to 112 tools (up to 600 mm | 23.6 in tool length)

• Machine prepared for automatic pallets system

• Exhaustion system

• Electronic probe and Laser measuring system

Technical data

| Machine model SIC | 650 | |

| CNC Axis | ||

| W drilling one stroke | 1120 mm | 44.1 in |

| X longitudinal travel | 650 mm | 25.6 in |

| Y’ vertical travel | 6840 mm | 33.1 in |

| Z cross travel | 500 mm | 19.7 in |

| B table rotation | 360,000 | |

| A table tilting | +90º/-45º | |

| Drilling capacity | ||

| Max. drilling (one-step) | 760 mm | 29.9 in |

| Drilling capacity | ø4-25 mm | ø0.16-0.99 in |

| Milling capacity | ||

| Milling | 250 cm3/min | 15.3 in3/min |

| Rigid tapping | M 16 | |

| Helical threading | Standard | |

| Spindle unit | ||

| Spindle taper | HSK-A63 | |

| Speed | 0-11800 rpm | |

| Power | 21/26 kW | 28/35 hp |

| Torque | 80/101 Nm | 59/75 ft-lbs |

| Automatic rotary table | ||

| Table size | 500×500 mm | 19.7×19.7 in |

| Positioning type | 360,000 | |

| Max. load in rotation | 750 kg | 1,654 lbs |

| Layout dimensions | ||

| Total weight | 14 Ton | 30,865 lbs |

| Foot print (WxL) | 6790×3160 mm | 267.3×124.4 in |

MT 1500 | 2500

Standard equipment

CNC FAGOR 8065 Windows 7

• Electronic handwheel

• Digital drives

• Nitrogen double counterweight

• Absolute linear encoders in axis X, Y, Y1, Z

• Absolute angular encoders in axis A, B

• Telescopic covers in all axis (except W)

• RTCP/Kinematics

• Rigid tapping

• Quick change between drilling/milling

• Coolant tank with automatic filtering

• Submerged pumps for oil recirculation

• High pressure pump 80 bar, 100 l/min | 1,160 psi, 26.5 gal/min

• Automatic chip conveyor

• Complete cover with doors, glass windows and ceiling

Optional equipment

• CNC HEIDENHAIN TNC 640

• Wise software system

• ATC up to 250 tools (up to 600 mm | 23.6 in tool length)

• Mirror version

• Spindle gearbox

• Y axis = 1500 mm | 59.1 in

• W axis = 2000 mm | 78.7 in

• Exhaustion system

• Electronic probe and Laser measuring system

Technical data

| Model MT | 1500 | 2500 | ||

| CNC Axis | ||||

| W drilling one stroke | 1630 mm | 64.2 in | 1630 mm | 64.2 in |

| X longitudinal travel | 1500 mm | 59.1 in | 2500 mm | 98.4 in |

| Y vertical travel | 1000 mm | 39.4 in | 1200 mm | 47.2 in |

| Z cross travel | 650 mm | 25.6 in | 650 mm | 25.6 in |

| B table rotation | 360,000 | 360,000 | ||

| A tilting rotation | +25º/-25º | +25º/-25º | ||

| Drilling capacity | ||||

| Max. drilling stroke W+Z | 1630+650 mm | 64.2+25.6 in | 1630+650 mm | 64.2+25.6 in |

| Drilling capacity | ø5-40 mm | ø0.2-1.58 in | ø5-40 mm | ø0.2-1.58 in |

| Milling capacity | ||||

| Milling | 400 cm3/min | 24.4 in3/min | 500 cm3/min | 30.5 in3/min |

| Rigid tapping M30 M32 M34 | M 32 | M34 | ||

| Helical threading | Standard | Standard | ||

| Spindle unit | ||||

| Spindle taper | ISO 50 | DIN 69871 | ISO 50 | DIN 69871 |

| Speed | 0-4500 rpm | 0-4500 rpm | ||

| Power | 15/22 kW | 20/30 hp | 22/33 kW | 30/45 hp |

| Torque | 191/287 Nm | 141/212 ft-lbs | 280/420 Nm | 207/310 ft-lbs |

| Automatic rotary table | ||||

| Table size | 1300×1300 mm | 51.2×51.2 in | 1600×1300 mm | 63.0×51.2 in |

| Positioning type | 360,000 | 360,000 | ||

| Max. load in rotation | 10 Ton | 22,047 lbs | 15 Ton | 33,070 lbs |

| Layout dimensions | ||||

| Total weight | 29 Ton | 63,935 lbs | 34Ton | 74,958 lbs |

| Foot print (WxL) | 5090×5500 mm | 200.4×216.5 in | 6090×5500 mm | 239.8×216.5 in |

5 axis machines

PWN 1000 | 2000 | 3000

Standard equipment

• CNC FAGOR 8065

• Electronic handwheel

• Digital drives

• Nitrogen double counterweight

• Absolute angular encoders in axis B

• Telescopic covers in all axis (except W)

• RTCP/Kinematics

• Rigid tapping

• Quick change between drilling/milling

• Coolant tank with automatic filtering

• Submerged pumps for oil recirculation

• High pressure pump 80 bar, 100 l/min | 1,160 psi, 26.5 gal/min

• Automatic chip conveyor

• Complete cover with doors, glass windows and ceiling

Optional equipment

• CNC HEIDENHAIN TNC 640

• Wise software system

• ATC up to 250 tools (up to 600 mm | 23.6 in tool length)

• ATC Gun drill up to 5 tools

• Absolute linear encoders in axes X, Y, Z

• Spindle gearbox

• Y axis = 1500 mm | 59.1 in

• W axis = 2000 mm | 78.7 in

• Exhaustion system

• Electronic probe and Laser measuring system

Technical data

| Model PWN | 1000 | 2000 | 3000 | |||

| CNC Axis | ||||||

| W drilling one stroke | 1630 mm | 64.2 in | 1630 mm | 64.2 in | 1630 mm | 64.2 in |

| X longitudinal travel | 1000 mm | 39.4 in | 2000 mm | 78.7 in | 3000 mm | 118.1 in |

| Y vertical travel | 800 mm | 31.5 in | 1200 mm | 47.2 in | 1200 mm | 47.2 in |

| Z cross travel | 800 mm | 31.5 in | 800 mm | 31.5 in | 800 mm | 31.5 in |

| B table rotation | 360,000 | 360,000 | 360,000 | |||

| Drilling capacity | ||||||

| Max. drilling stroke W+Z | 1630+800 mm | 64.2+31.5 in | 1630+800 mm | 64.2+31.5 in | 1630+800 mm | 64.2+31.5 in |

| Drilling capacity | ø5-40 mm | ø0.2-1.58 in | ø5-40 mm | ø0.2-1.58 in | ø5-40 mm | ø0.2-1.58 in |

| Milling capacity | ||||||

| Milling | 300 cm3/min | 18.3 in3/min | 400 cm3/min | 24.4 in3/min | 500 cm3/min | 30.5 in3/min |

| Rigid tapping M30 M32 M34 | M 30 | M32 | M34 | |||

| Helical threading | Standard | Standard | Standard | |||

| Spindle unit | ||||||

| Spindle taper | ISO 50 | DIN 69871 | ISO 50 | DIN 69871 | ISO 50 | DIN 69871 |

| Speed | 0-4500 rpm | 0-4500 rpm | 0-4500 rpm | |||

| Power | 11/15 kW | 15/20 hp | 15/22 kW | 20/30 hp | 22/33 kW | 30/45 hp |

| Torque | 140/200 Nm | 103/148 ft-lbs | 191/287 Nm | 141/212 ft-lbs | 280/420 Nm | 207/310 ft-lbs |

| Automatic rotary table | ||||||

| Table size | 1300×1300 mm | 51.2×51.2 in | 1600×1300 mm | 63.0×51.2 in | 1800×1600 mm | 70.9×63.0 in |

| Positioning type | 360,000 | 360,000 | 360,000 | |||

| Max. load in rotation | 10 Ton | 22,047 lbs | 20 Ton | 44,093 lbs | 30 Ton | 66,139 lbs |

| Layout dimensions | ||||||

| Total weight | 21 Ton | 46,298 lbs | 23 Ton | 50,707 lbs | 28 Ton | 61,730 lbs |

| Foot print (WxL) | 5000×5510 mm | 196.8×216.9 in | 5970×5510 mm | 235.0×216.9 in | 6725×5850 mm | 264.8×230.3 in |

5 axis machines

CCN 1000

Standard equipment

• CNC FAGOR 8055i Power

• Electronic handwheel

• Digital drives

• Nitrogen double counterweight

• Absolute angular encoders in axis B

• Telescopic covers in all axis (except W)

• RTCP/Kinematics

• Rigid tapping

• Quick change between drilling/milling

• Coolant tank with automatic filtering

• Submerged pumps for oil recirculation

• High pressure pump 70 bar, 90 l/min | 1,015 psi, 23.8 gal/min

• Automatic chip conveyor

• Complete cover with doors, glass windows and ceiling

Optional equipment

CNC HEIDENHAIN TNC 640

CNC FAGOR 8060-M

• CNC HEIDENHAIN TNC 620

• Wise software system

• ATC 24/40 tools

• Absolute linear encoders in axes X, Y, Z

• Exhaustion system

• Electronic probe and Laser measuring system

Technical data

| Model CCN | 1000 | |

| CNC Axis | ||

| W drilling one stroke | 1550 mm | 44.1 in |

| X longitudinal travel | 1000 | 39.4 in |

| Y’ vertical travel | 600 mm | 23.6 in |

| Z cross travel | 500 mm | 19.7 in |

| B table rotation | 360,000 | |

| Drilling capacity | ||

| Max. drilling stroke W+Z | 1550+500 mm | 61.0+19.7 in |

| Drilling capacity | ø4-25 mm | ø0.16-0.99 in |

| Milling capacity | ||

| Milling | 250 cm3/min | 15.3 in3/min |

| Rigid tapping | M 22 | |

| Helical threading | Standard | |

| Spindle unit | ||

| Spindle taper | ISO 40 DIN 69871 | |

| Speed | 0-6000 rpm | |

| Power | 5,5/7,7 kW | 7,5/10,5 hp |

| Torque | 52,5/73,5 Nm | 38.7/54.2 ft-lbs |

| Automatic rotary table | ||

| Table size | 1000×1000 mm | 39.4×39.4 in |

| Positioning type | 360,000 | |

| Max. load in rotation | 4 Ton | 8,819 lbs |

| Layout dimensions | ||

| Total weight | 14 Ton | 30,865 lbs |

| Foot print (WxL) | 6340×5380 mm | 249.6×211.8 in |

For all inquiries and more info about our machines please contact us by:

Phone: +351 256 247 970

email: info@cheto.eu