Plate thickness from 2mm to 40mm, helix pitch 40 to 1400mm, diameter 80mm to 3000mm

The mechanical screw flight helix conveyors are used to move liquids and solid through a spiral system: an endless screw, which, by rotating on its axis, carries the material all the way to its destination, both horizontally and vertically.

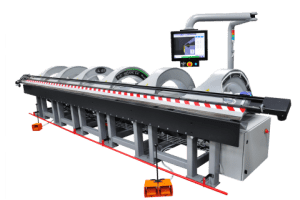

MG designs and manufactures machines for the industrial production of screws flights and spirals, in order to satisfy all customer needs: divide, combine, select and deliver any type of material.

Furthermore, MG is able to make large spiral machines that are used for the production of pumps, kneaders, mixers, augers and industrial turbines.

Applications and Markets: Chemical, pharmaceutical, flour milling, food processing, steel, shipbuilding, renewable energy, waste recycling, mining, handling of bulk materials.

MG’s machines are designed to mount different and adjustable molds that easily allow varying the production parameters of the screw flight: inner diameter, outer diameter, pitch of the spiral, the thickness of the materials used.

They can perform spirals with reduced pitch, a longer pitch, or standard pitch.

In addition, it can work without problems both the right-side spiral (with clockwise rotation), and left-side spiral (with rotation in a counter-clockwise).

The wide flexibility is very wide: inner diameter from 40 mm, outside diameter up to 3.000 mm, while the pitch can vary between 40 mm and 1.400 mm. The augers produced with MG’s machines can be endless spiral, tape, vane wheel (with constant pitch, or progressive, or tapered). Furthermore, every type of screw flight without interior shaft, to carry blocking materials.

Customer needs are always met, as we are able to work materials with thickness ranging from 2 mm to 40 mm. The range of materials that can be used with MG machines is very wide: carbon steel (S235JR, S275JR, S355JR), stainless steel (AISI 304, AISI 316

and 400 series), wear-resistant steels (T1, Hardox 400, CReUsABRO 321, 4800). MG’s major strength is the close integration with the command and control software. A configured tool that takes into account the material spring back and that puts in mathematical relation all working parameters: working cycle of the client’s machine, pitch and angle of development of the screw flight, outside and inside diameter, thickness and type of ‘steel work. According to the thrust of the screw and the stopping position, MG / Delsy software will determine the pitch of the spiral, integrating it with all the other data. Before starting production, the parameters are graphically displayed on the control screen; they are stored in the memory and can be used for future operations with similar

parameters. This automated process can cut manual operations: MG’s screw flight machines can draw the correct parameters from the software and work without error right from the beginning. Each MG machine can be adapted to suit any market need.

Our technical departments interacts and closely works with the customer to design special solutions for any particular kind of production.

ADVANTAGES OF MG’S EXCLUSIVE TECHNOLOGY:

• Movable and interchangeable heads

• Tilting tools for workings with different pitches

• Geometric and functional consistency of products

• Wide range of spirals and screw flight working processes

• Integration between the control software and machine tool

• Production without mistakes, even if operators have limited experience

• Efficient and economical with individual pieces or small series

• Safe operation low maintenance costs

• Production waste is completely reset

TECHINCAL DATA

| Model | Unit | EM 500 | EM 1500 | EM 2000 | EM 2500 | EM 3000 |

| Plate Thickness Min | mm | 2 | 6 | 6 | 10 | 10 |

| Plate Thickness Max | mm | 12 | 30 | 30 | 40 | 40 |

| Helix Pitch Min | mm | 40 | 60 | 100 | 100 | 100 |

| Helix Pitch Max | mm | 500 | 800 | 1000 | 1200 | 1400 |

| Outside Diameter Min | mm | 80 | 120 | 1300 | 1300 | 1300 |

| Outside Diameter Max | mm | 1000 | 1600 | 2000 | 2500 | 3000 |

For all inquiries and more info about our machines please contact us by:

Phone: +39 0172 691 327

email: info@mgsrl.com