CNC Vertical Turning Lathes in series BasicTurn, Powerturn, Forceturn, Experturn

Table diameters from 800 to 4000 mm

Basicturn

Machine Characteristics:

- Frame with high rigidity and stability

- Design emphasizing functionality and easy maintenance

- Available C-axis control, and rotary tool drive

- Automatic exchange of turning tool holders and rotary tools

- Ram designed for efficient and precise machining

- Variable height of the working area

- Through-the-tool coolant supply optional

- Up-to-date and user-comfortable control

- Pre-defined configurations enable quick machine delivery

- Available control systems: Siemens or Fanuc

Powerturn

Machine Characteristics:

- Well-proven frame design which guarantees high rigidity and stability during machining

- High variability of tooling and measuring probes

- Automatic exchange of tool heads, tool holders and modular tools

- Tool magazine which can be configured to the customer’s requirements

- Very precise table positioning (C-axis) and rotary tool drive with high power output

- As an option, the machine can be equipped with automatic pallet exchange

- Optional high-pressure cooling

- Completely closed machining area

- Possibility to connect an exhauster

- Extra travel range in the X-axis in both directions from the table centre

- Available control systems: Siemens or Fanuc

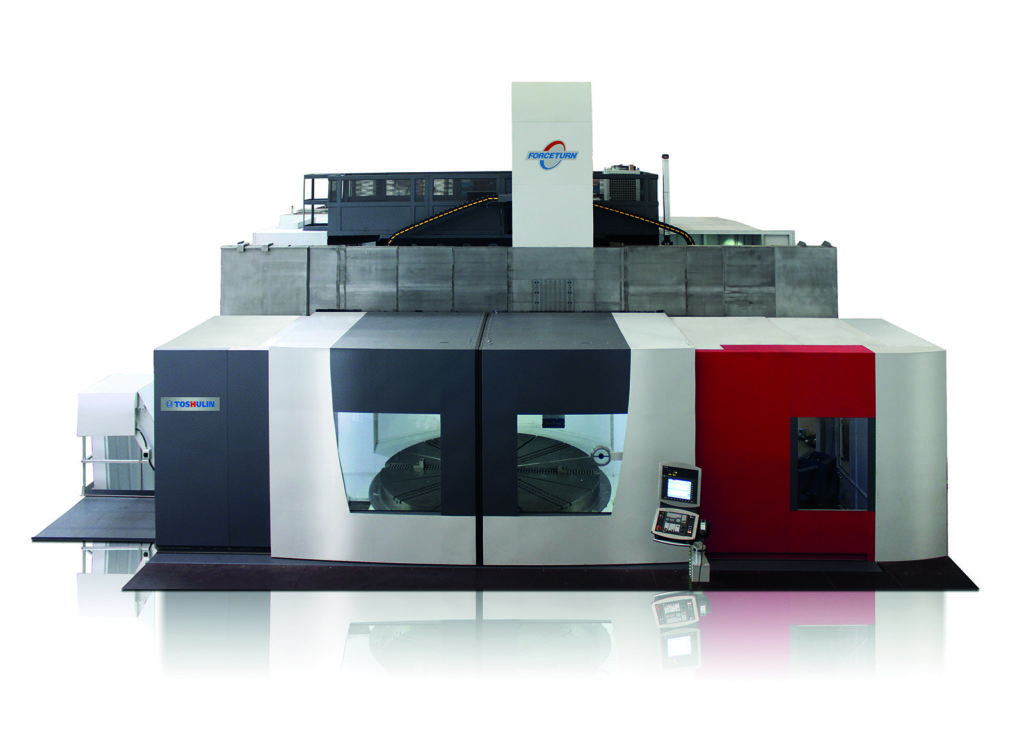

Forceturn

Machine Characteristics:

- High and stable machine frame from cast iron specified for high-efficient machining

- Optional guiding with bearing packs or hydrostatic guiding in the linear axes

- Ram is designed for the most efficient machining

- Extremely rigid table bearing using the hydrostatic bearing

- Very precise table positioning (C-axis) and rotary tool drive with high power output

- Optional high-pressure cooling

- Great variability of tooling

- Automatic exchange of tool heads, tool holders and modular tools

- Extra travel range in the X-axis in both directions from the table centre

- Effective protective guards against splashing coolant

- Control systems Siemens or Fanuc

Experturn

Machine Characteristics:

- High degree to adapt the machine configuration

- Extraordinary rigid and stable machine frame from cast iron

- Ram designed for high-efficient machining

- Very precise table positioning (C-axis) and rotary tool drive with high power output

- Optional guiding with bearing packs or hydrostatic guiding in the linear axes

- Table bearing – optional antifriction bearing or hydrostatic bearing

- Optional Y-axis control

- As an option, the machine can be equipped with automatic pallet exchange

- Extensive range of tooling and measuring probes

- Automatic exchange of tool heads, tool holders and modular tools

- Optional tool heads offer supplementary axes: B-head, C‑head, Y-head

- Machine accuracy adapted to the customer’s requirements

- Possibility to implement high-pressure cooling – HPC or UHPC

Technical data

| Machine | Table diameter | Max workpiece diameter | Max workpiece height | Max workpiece weight | Max table speed |

| [mm] | [mm] | [mm] | [kg] | [rev. min-1] | |

| BASICTURN | 1250 | 1400 | 1900 | 8000 | 630 |

| 1600 | 2000 | 2000 | 12 000 | 400 | |

| 2000 | 2300 | 2000 | 20 000 | 315 | |

| 2500 | 2900 | 2540 | 25 000 | 250 | |

| 3000 | 3600 | 2540 | 25 000 | 200 | |

| 4000 | 5000 | 2480 | 25 000 | 150 | |

| POWERTURN | 800 | 1000 | 1400 | 5000 | 1000 |

| 1000 | 1400 | 1800 | 8000 | 800 | |

| 1250 | 1500 | 1800 | 8000 | 630 | |

| 1600 | 2000 | 2500 | 12 000 | 400 | |

| 2000 | 2300 | 2500 | 20 000 | 315 | |

| 2500 | 2900 | 3140 | 25 000 | 250 | |

| 3000 | 3600 | 3140 | 30 000 | 200 | |

| 4000 | 5000 | 3080 | 30 000 | 150 | |

| FORCETURN | 2500 | 2900 | 4000 | 45 000 | 250 |

| 3000 | 3600 | 4000 | 45 000 | 200 | |

| 4000 | 5000 | 5000 | 60 000 | 150 | |

| EXPERTURN | 800 | 1000 | 1400 | 5000 | 1000 |

| 1000 | 1400 | 1800 | 8000 | 800 | |

| 1250 | 1500 | 1800 | 8000 | 630 | |

| 1600 | 2000 | 2500 | 12000 | 400 | |

| 2000 | 2300 | 2500 | 20000 | 315 | |

| 2500 | 2900 | 3140 | 25000 | 250 | |

| 3000 | 3600 | 3140 | 30000 | 200 | |

| 4000 | 5000 | 3080 | 30000 | 150 |

For all inquiries and more info about our machines please contact us by:

Phone: +420 573 327 265

email: klara.zambochova@toshulin.cz