CNC Vertical milling machines Series: FNG, FV

Table sizes 800×400, 900×500, 305×1300 mm

Table loads up to 360 kg

Toolroom milling machine with continuous control FNG 40 CNC A

The machine FNG40 CNC A is continuously controlled toolroom milling machine designed to cover a wide range of milling, drilling, boring and thread cutting operations on workpieces up to 350 kg weight.

This machine is especially suitable for tool-making workshops.

The machine is equipped with horizontal spindle which is fitted in the ram-type spindle head and also with vertical milling head which can be tilted in the range ± 90°.

The machine is delivered with vertical milling head , swing away arm for this head (Special execution) and fixed angular table.

The perfect clamping of tool is realized by pneu-hydraulic clamping in both vertical and horizontal spindle.

Spindle drive is by means of electromotor with stepless regulation of revolutions.

The stepless spindle speeds are divided into 2 steps in range 50-4000 r.p.m

The optimum lubrication of guideways is solved by means of lubriction pump with dosing devices.

Cooling equipment of tools, working light and working space guard are delivered as standard accessories.

ADVANTAGES:

- Vertical spindle

- Stepless spindle speeds by means of frequency convertor in 2 steps

- Full output of the spindle from 450 rpm

- Direct measure system in 3 axes

- Pneu-hydraulic tool clamping

- Hardened guideways, mating faces are covered with TURCITE

- Simple and comfortable operation, compact layout

- Central lubrication by means of dosing devices

- Wide range of technological possibilities

- High rigidity, accuracy and reliability of the machine

- Efficient working space guard

- Easy maintenance

- Modern design and perfect surface finish with oil-resistant painting

MACHINE EXECUTION

Standard execution:

- Control system HEIDENHAIN TNC 320

- Fixed angular table 800 x 400 mm

- Vertical milling head

- Pneu-hydraulic tool clamping

- Central lubrication with dosing devices

- Tool cooling equipment

- Electrical equipment for 3 x 400V/50 cycles

- Painting of machine – blue and grey color RAL 5010/RAL 9002

- Lighting of working space

- Working space guard

Special execution:

(must be required in the order)

- Machine equipped with other drives

- Other control system

- Electronic hand wheel

- Cabin cover

- Automatic tool change

- Machine in another execution than 3 x 400V/50 cycles

- Machine with another painting

- Horizontal spindle

Technical data

| FNG 40 | |||

| Table size | mm | 800×400 | |

| Clamping slots | – number | 7 | |

| – width and spacing | mm | 14×50 | |

| Max. table load | kg | 350 | |

| Travel | – longitudinal X | mm | manual/machine —/600* |

| – cross Y | mm | manual/machine —/400* | |

| – vertical Z | mm | manual/machine —/400* | |

| Feeds | stepless | ||

| – range X,Y | mm/min. | 1-8500 | |

| Z | mm/min. | 0-7000 | |

| Rapid traverse | X,Y | mm/min. | 8500 |

| Z | mm/min. | 7000 | |

| HORIZONTAL SPINDLE | ISO 40 | ||

| Distance of spindle axis to working surface of fixed table | mm | 148-548 | |

| Revolutions | – stepless | r.p.m. | 50-4000 |

| Revolutions – number of rates | 2 | ||

| Spindle speed change | stepless | ||

| VERTICAL SPINDLE | ISO40 | ||

| Distance of spindle axis from frame quide ways | mm | 250-650 | |

| Revolutions | – stepless | r.p.m. | 50-4000 |

| Revolutions – number of rates | 2 | ||

| Spindle speed change | stepless | ||

| Spindle swivelling | ±90° | ||

| MACHINE | |||

| Motor power | kW | 5,5 | |

| Total power input | kVA | 20 | |

| Weight | kg | 2750 | |

| Floor space | mm | 3723×2845 | |

| Height | mm | 2120 |

Toolroom milling machine with continuous control FNG 50 CNC A

The machine FNG50 CNC A is continuously controlled toolroom milling machine designed to cover a wide range of milling, drilling, boring and thread cutting operations on workpieces up to 350 kg weight.

This machine is especially suitable for tool-making workshops.

The machine is equipped with horizontal spindle which is fitted in the ram-type spindle head and also with vertical milling head which can be tilted in the range ± 90°.

The machine is delivered with vertical milling head , swing away arm for this head (Special execution) and fixed angular table.

The perfect clamping of tool is realized by pneu-hydraulic clamping in both vertical and horizontal spindle.

Spindle drive is by means of electromotor with stepless regulation of revolutions.

The stepless spindle speeds are divided into 2 steps in range 50-4000 r.p.m

The optimum lubrication of guideways is solved by means of lubriction pump with dosing devices.

Cooling equipment of tools, working light and working space guard are delivered as standard accessories.

ADVANTAGES:

- Horizontal and vertical spindle

- Stepless spindle speeds by means of frequency convertor in 2 steps

- Full output of the spindle from 450 r.p.m.

- Direct measure system in 3 axes

- Pneu-hydraulic tool clamping

- Hardened guideways, mating faces are covered with TURCITE

- Simple and confortable operation, compact layout

- Central lubrication by means of dosing devices

- Wide range of technological possibilities

- High rigidity, accuracy and reliability of the machine

- Efficient working space guard

- Easy maintenance

- Modern design and perfect surface finish with oil-resistant painting

MACHINE EXECUTION

Standard execution:

- Control system HEIDENHAIN TNC 320

- Fixed angular table 900 x 500 mm

- Vertical milling head

- Pneu-hydraulic tool clamping

- Central lubrication with dosing devices

- Tool cooling equipment

- Electrical equipment for 3 x 400V/50 cycles

- Painting of machine – blue and grey color RAL 5010/RAL 9002

- Lighting of working space

- Working space guard

Special execution:

(must be required in the order)

- Machine equipped with other drives

- Other control system

- Electronic hand wheel

- Cabin cover

- Automatic tool change

- Machine in another execution than 3 x 400V/50 cycles

- Machine with another painting

- Horizontal spindle

Technical data

| FNG 50 CNC A | |||

| Table size | mm | 900×500 | |

| Clamping slots | – number | 9 | |

| – width and spacing | mm | 14×50 | |

| Max. table load | kg | 350 | |

| Travel | – longitudinal X | mm | manual/machine —/700* |

| – cross Y | mm | manual/machine —/500* | |

| – vertical Z | mm | manual/machine —/500* | |

| Feeds | stepless | ||

| – range X,Y | mm/min. | 1-8500 | |

| Z | mm/min. | 0-7000 | |

| Rapid traverse | X,Y | mm/min. | 8500 |

| Z | mm/min. | 7000 | |

| HORIZONTAL SPINDLE | ISO 40 | ||

| Distance of spindle axis to working surface of fixed table | mm | 148-548 | |

| Revolutions | – stepless | r.p.m. | 50-4000 |

| Revolutions – number of rates | 2 | ||

| Spindle speed change | stepless | ||

| VERTICAL SPINDLE | ISO40 | ||

| Distance of spindle axis from frame quide ways | mm | 250-650 | |

| Revolutions | – stepless | r.p.m. | 50-4000 |

| Revolutions – number of rates | 2 | ||

| Spindle speed change | stepless | ||

| Spindle swivelling | ±90° | ||

| MACHINE | |||

| Motor power | kW | 5,5 | |

| Total power input | kVA | 20 | |

| Weight | kg | 2872 | |

| Floor space | mm | 3723×2845 | |

| Height | mm | 2120 |

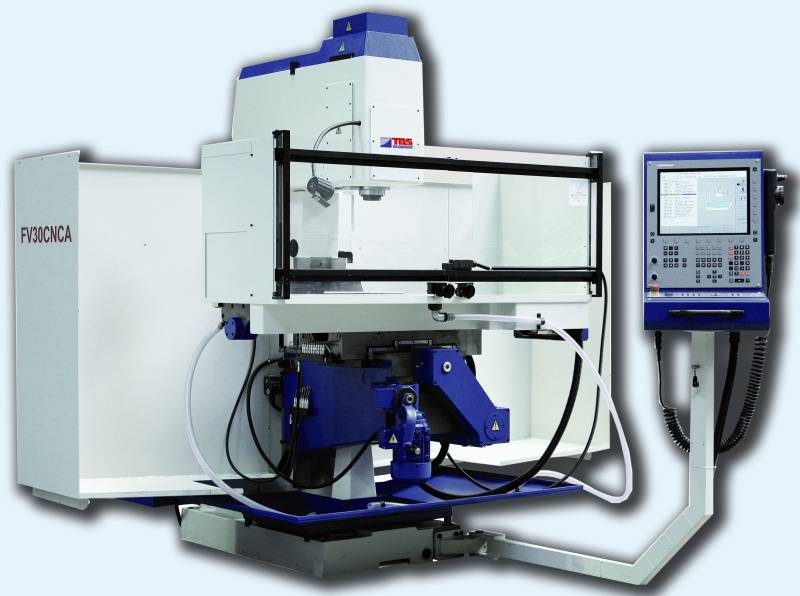

Vertical milling machine with continuous control FV 30 CNC A

Milling machine FV30 CNC A is continuously controlled milling machine, where the quill with the spindle performs controlled motion in the vertical axis.

This machine is characterized by very suitable proportion of the price to technical features.

The machine can be used with advantage in production of complicated small and middle parts with large number of drilling, boring and threading operations.

The rigid spindle head and spindle drive with the belt transmission enable smooth machining in the highest revolutions.

Driving mechanism and wide extend of spindle revolutions enable effective milling of all metals from tool steels to alloys of light metals.

ADVANTAGES:

- High accuracy of positioning

- Hardened guideway, mating surface lined by special material TURCITE

- Spindle in shifting quill

- Full output of the spindle from 400 r.p.m.

- High rigidity

- Pneumatic spindle speed change

- Pneu-hydraulic tool clamping

- Central lubrication system

- Compact machine design

- Modern design and perfect surface finish with oil-resistant painting

MACHINE EXECUTION

Standard execution:

- Safety guard of working space

- Control system HEIDENHAIN Control system TNC 320, iTNC 530

- Servo drives TELEMECANIQUE

- Spindle motor 5,5 kW

- Revolutions range 50-6000 r.p.m.

- Motor-operated knee elevator

- Electrical equipment for 400V/50 cycles

- Painting of machine – blue and grey color RAL 5010/RAL 9002

- Lighting of working space

Special execution:

(must be required in the order)

- machine with other drives

- automatic tool change with tool magazine for 12 tools

- Machine equipped with another control system

- Machine in another execution than 3 x 400V/50 cycles

- Electronical Handwheel (for HEIDENHAIN control)

- Measuring probe (for HEIDENHAIN control)

- Machine with another painting

- Digital read-out of knee position

- Machine with 4th axis

- Bigger guard of working space

Technical data

| FV30 CNC A | mm | 305×1300 | |

| Clamping slots | – number | 3 | |

| – width and spacing | mm | 14×80 | |

| Maximal table load | kg | 360 | |

| Travel | – longitudinal X | mm | 760 |

| – cross Y | mm | 380 | |

| – vertical Z (by quill) | mm | 152 | |

| Vertical adjustment of the knee | mm | 450 | |

| Feeds | -stepless X,Y,Z | mm/min. | 2,5-3000 |

| Rapid traverse | X,Y | mm/min. | 7000 |

| Z | mm/min. | 5000 | |

| SPINDLE | ISO 40 | ||

| Distance of spindle axis from frame guide ways | mm | 375 | |

| Revolution | – numbers of rates | 2 | |

| – range revolutions (stepless) | r.p.m. | 50-6000 | |

| Motor power | kW | 5,5 | |

| MACHINE | |||

| Total power input | kVA | 22 | |

| Weight | kg | 2300 | |

| Floor space | mm | 2646×3182 | |

| Height | mm | 2250 |

For more information about our machines you may contact us by:

Phone: +420 587 404 203

e-mail: tos@tos-olomouc.cz