Fiber lasers with working area from 1500×3000 up to 2000×6000 mm

Characteristics

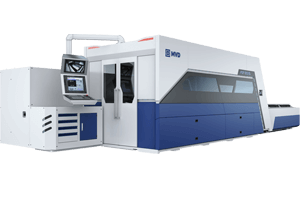

Diamond Fiber Laser cutting machine that operates with a fiber laser technology. It is dedicated to users whose priority is speed and the highest cutting precision also in complicated contours. The utilization of fiber laser technology significantly decreases the complexity of laser system and directly reduces operating costs compared to CO2 laser technology. Individual consumer’s needs are ensured by the application of compact gantry construction that enhances stability, completely closed safety cabinet protecting against laser radiation and capability of adjusting the working area dimensions.

Main features

- state-of the art cutting technology

- capability of processing a wide range of reflective materials (copper, brass, polished materials)

- long-term reliability ensured by the highest quality components produced by renowned manufactures

- innovative PCS system which is able to analyze and precisely select piercing time with accordance to the material applied (optional)

- optional instalment of linear actuators to replace servomotors

- fully automated cutting process with load and unload of the plates (optional)

Technology

Construction

Portal construction assures stability and endurance of the whole machine. Completely closed safety cabinet covering the entire cutting area and the utilization of exchangeable pallet tables increase the work safety. The construction of the railway is based high precision linear slides and modern servo motors to guarantee accuracy cutting head set-up, high dynamics and trouble-free operations.

ECS872 Control Panel

ECS872 centre is a high quality industrial device, equipped with touch screen. Efficient components and construction resistant to extreme production conditions guarantee failure free operation. Unsurpassed functionality of proprietary software and intuitive drive interface enable full exploitation of the machine’s capacity.

Automatic pallet table

Exchangeable pallet table consists of two working areas which enable the possibility of alternate entering and departing the working area allowing the unloading of finished elements and loading new material. Pallet table is equipped with belt feeder responsible for collecting elements which are to small to retain on the grate. The table is equipped with safety laser gates to realize the required safety of work.

Cutting head with PCS

Precitec cutting head ensures exceptional reliability and cutting quality. Integrated distance sensor safeguards stability and prevents collisions. To protect its high grade optical components, this cutting head is fitted with a protective glass which is located in the cartridge. Optionally installed, innovative PCS (Piercing Control System) controls the laser beam emission while enhancing efficiency and productivity.

Technical data

| Model | Diament Fiber Laser 2 |

| Drives | Servo AC |

| Working area | 1500 x 3000, 2000 x 4000, 2000 x 6000 mm |

| Z axis movement | 115 mm |

| Max. axis positioning speed (X,Y) | 120 m/min |

| Positioning accuracy | +/- 0,03 mm |

| Laser beam power | 1000 – 6000 W |

Standard laser sources

| Resonator | YLS–1KW | YLS-2KW | YLS-3KW | YLS-4KW | YLS-5KW | YLS-6KW |

| Power (W) | 1000 | 2000 | 3000 | 4000 | 5000 | 6000 |

| Recommended cooling capacity (kW) | 2,1 | 4,2 | 6,4 | 8,5 | 10,4 | 12,6 |

| Electrical connection (kW) | 32,1 | 6,1 | 9,1 | 12,1 | 15,1 | 18,2 |

| Max. material thickness | YLS-1KW | YLS-2KW | YLS-3KW | YLS-4KW | YLS-5KW | YLS-6KW |

| Mild steel (mm) | 10 | 15 | 18 | 20 | 22 | 25 |

| Stainless steel (mm) | 4 | 8 | 10 | 12 | 15 | 20 |

| Aluminium (mm) | 4 | 8 | 10 | 12 | 15 | 15 |

For all inquiries and more info about our machines please contact us by:

Phone: +48 606 676 517

email: handlowy@eckert.com.pl