CNC Routers and CNC Engravers

working sizes from 320 x 215 mm up to 2100 x 6200 mm

for machining metal, polymer and wood materials

in several machine series:

NOTUS

NOTUS PLUS

DIGI

DIGI CORSA

MISTRAL

MT PROFI

ECO router

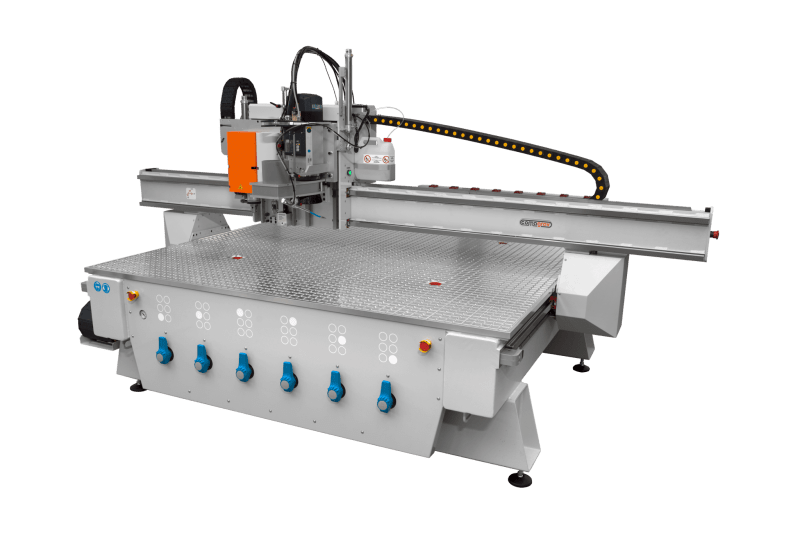

COMAGRAV NOTUS PLUS

COMAGRAV NOTUS PLUS is the best Czech multifunctional CNC router with rich equipment for professional production.

The massive design and high-quality welding of the frame ensures precise routing and longevity.

Working sizes are from 2100 x 1600 up to 2100 x 6200 mm

It can be used for:

- production of plastic parts

- sign making

- metal industry

- packaging industry

- serial production

- production of models

Technical specifications:

Workspace

| Notus Plus 1600 | 2100 x 1600 mm |

| Notus Plus 3000 | 2100 x 3150 mm |

| Notus Plus 4000 | 2100 x 4200 mm |

| Notus Plus 6000 | 2100 x 6200 mm |

Parameters

| Z axis movement | 250 mm (optionally more) |

| Space under gantry | 140 mm (optionally more) |

| Maximal speed | 500 mm/s – 30 m/min (optionally up to 800 mm/s – 48 m/min) |

| Resolution | 0,00078 mm |

| Spindle power | up to 13,2 kW |

| Spindle speed | up to 50 000 RPM |

| Control system | PILOT A+ 3D controller |

Serial equipment

| Automatic Z sensor for setting of starting point |

| Emergency safety STOP buttons |

| X-axis double drive |

| Precise T-slot aluminium work table with clamps, or vacuum table |

| 3D routing and cutting software Vectric |

| DELL PC with 3 year warranty NBD |

Optional equipment

| Spindle with pneumatic clamping for automatic tool change |

| Linear tool tray |

| Carousel tool tray with tool presence sensor |

| Spray cooling system (PROFI or standard) |

| High pressure vacuum table |

| Dust collector |

| MULTI head |

| Camera system for cutting with registration marks |

| Rotary adapter |

Mechanics

| 3-axis CNC table |

| strong construction welded steel, steel portal |

| stress relieved construction |

| accurate ball linear guide in XYZ axes, covered guide, ball screw in Z axis |

| helical racks with pinion and planetary gearbox in XY axes, double X-axis drive with automatic perpendicularity adjustment |

| powerful Mitsubishi servomotors and high-precise planetary gearboxes |

| high-pressure vacuum table or table with T-slot |

COMAGRAV NOTUS

COMAGRAV NOTUS is a professional CNC router for routing and cutting. It brings AC servo technology for maximum reliability and to achieve high cutting speeds. Everyone can choose from a wide range of work tables and spindles with an output of up to 9.6 kW. There are many cutting units to choose from for cutting materials. Machines from the COMAGRAV NOTUS family works in many industries in advertising production, in the production of prototypes, to demanding workshops with mass production.

Workspace from 1000 x 1500 mm to 2040 x 4200 mm.

Z axis movement min. 175 mm, max. 450 mm.

Technical specifications

Workspace

| COMAGRAV NOTUS 1015 (type with raised Z axis) | 1000 x 1500 mm |

| COMAGRAV NOTUS 1515 | 1550 x 1500 mm |

| COMAGRAV NOTUS 1526 | 1550 x 2600 mm |

| COMAGRAV NOTUS 1530 | 1550 x 3150 mm |

| COMAGRAV NOTUS 2030 | 2040 x 3150 mm |

| COMAGRAV NOTUS 2040 | 2040 x 4200 mm |

Parameters

| Z axis movement | 175 mm (450 mm NOTUS 1015) |

| Space under gantry | 140 mm (300 mm Notus 1015) |

| Maximal speed | 500 mm/s – 30 m/min (optionally up to 1100 mm/s – 66 m/min) |

| Resolution | 0,00078mm |

| Spindle power | up to 9,6 kW |

| Spindle rotation | up to 50.000 RPM |

| Control system | PILOT A+ 3D controller |

Serial equipment

| Automatic Z sensor for setting of starting point |

| Emergency safety STOP buttons |

| X-axis double drive |

| Precise T-slot aluminum work table with clamps (T-slot option) |

| High pressure phenol vacuum table (vacuum option) |

| Routing and cutting software Vectric |

| DELL PC with 3 year warranty NBD with control panel |

| Windows 10 IoT Enterprise operating system |

Optional equipment

| Spindles with pneumatic clamping for automatic tool change with a linear tray for 8 toolholders |

| Liquid cooled spindles |

| Carousel tool tray with tool presence sensor |

| Spray cooling system (PROFI or standard) |

| High pressure vacuum table made of aluminum |

| Dust collector |

| MULTI heads for cutting |

| (oscillating knives, direct cutting, engraving, etc.) |

| Camera system for cutting with registration marks |

| Vertical table |

| Rotary adapter |

Mechanics

| 3-axis CNC table |

| strong construction of steel profiles, steel portal |

| accurate ball linear guide in XYZ axes, ball screw in Z axis |

| helical racks with pinion and planetary gearbox in XY axes, double X-axis drive with automatic perpendicularity adjustment |

| powerful Mitsubishi servomotors and high-precise planetary gearboxes |

| high-pressure vacuum table or table with T-slot |

COMAGRAV ECO

COMAGRAV ECO is our basic CNC router for cutting and milling operations.

It is ideal for cutting plastic, aluminum, acrylic, wood, composite panels, MDF, plywood and similar materials.

Technical specifications

COMAGRAV ECO Parameters

| Working size | 1500×2500 mm |

| Frame | Prefabricated steel structure with crossbars |

| Working table | Vacuum with high pressure pump (2,4kW Becker with footswitch) or T-slots for fixture with clamps |

| Drivers | Stepper motors (microstep) in all axes, rack and pinion + planetary gears for XY, ballscrew for the Z axis |

| Spindle power | Professional electrospindle with an output of 2 kW |

| Maximum spindle speed | 24.000 RPM |

| Maximum speed | 100 mm/s |

| Maximum material height | 110 mm |

| Resolution | 0,0068720 mm |

| Weight | 400 kg T-slot, 540 kg Vacuum table |

| Collets | 6mm collet (ER20), wrenches for tightening |

| Z sensor | Z sensor for tool automatic tool lenght measuring |

| Control software | PILOT |

| Tool change | Manual |

| Camera system | Compatible with RIPs (option) |

| Control PC | DELL Corei3 (option) |

| Vacuum pump | Becker 2.4 kW high pressure (option) |

| OS | Windows 7/8/10 |

Options

| Control panel with DELL PC and Windows 10 IoT Enterprise |

| Camera system |

| Dust collector |

| Spray cooling system for aluminum cutting |

| Vacuum pump Becker 2.4 kW high pressure |

You can choose from two worktable solutions

T-slot aluminium worktable for manual fixing

The work table is made of precise aluminum profiles and allows clamping in T-slots.

High pressure vacuum worktable for automatic fixing

Solid worktable made of phenolic resin together with powerful Becker pump (2,4kW) is perfect and well-proven solution.

COMAGRAV MISTRAL

MISTRAL is an entrance product of the COMAGRAV family. With a working area of 1×1 m, it is ideal for smaller companies.

The robust and precise steel construction predestines MISTRAL for industrial operations and provides a long service life.

We offer a professional version with servomotors and a more affordable micro-step technology, which offers a good price in this category of machines.

CNC router, milling machine and engraving machine COMAGRAV MISTRAL works mainly in acrylics processing, advertising production, metal production and wood production.

Technical specifications

COMAGRAV MISTRAL 1000 Parameters

| Working size | 1100 x 1005 mm |

| Z axis movement | 130 mm |

| Z axis space under gantry | 130 mm |

| Maximum feed rate | 300 mm/s – 18 m/min servo version, or 150 mm/s – 9 m/min with stepper drive |

| Resolution | 0,00625 mm (servo version) or 0,01 mm |

| Spindle power | up to 3600 W |

| Spindle speed | up to 50.000 RPM |

| Control system | PILOT 3D controller via TCP/IP |

Standard equipment

| Automatic Z sensor |

| Emergency safety STOP buttons |

| Work table for high-pressure vacuum and oil-free high-pressure pump (vacuum variant) |

| Precise T-slot table with clamps (T-slot variant) |

| Routing software Vectric |

| Control panel with DELL PC (servo version), Windows 10 IoT Enterprise operating system |

Optional equipment

| Spray cooling system (PROFI or standard) |

| Automatic tool change with covered tray |

| Work table for high-pressure aluminum vacuum |

| Dust collecting |

| Mechanical scanning probe |

| Camera system for cutting with registration marks |

| Control panel with DELL PC (option for step version), Windows 10 IoT Enterprise operating system |

Mechanics

| 3-axis CNC table for routing and engraving |

| strong steel construction with aluminum portal |

| precise ball guide and ball screws in the XYZ axes |

| powerful servo or stepper motors |

For all inquiries and more info about our machines please contact us by:

Phone: +420 317 778 022

E-mail: info@comagrav.com