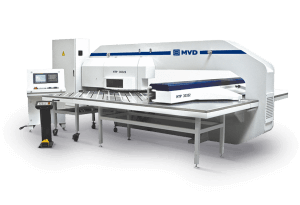

Punch press series Servo-Electric ETP-S and Hydraulic ETP punching system

Working dimensions: 1500 x 2000 mm up to 1500 x 3000 mm

Punching capacity: 20 and 30 tons

Machine features

• 20 tons and 30 tons power options

• Processing capacity up to 6 mm thick sheet metal

• Turret structure with housing

• Table options with different dimensions

• Ø88.9 maximum punching capacity

• Thick turret and index turret structure

• 27 station and 33 station options

• 3 automatic repositioning

sheet metal holding clamps

• O type mono-block rigid body structure

• Tool lubricating system

• Aluminium body axis structure

• Sheet metal loading system

• embedded into brush table

• Water cooled hammer system for Servo-Electric ETP-S series

Servo-Electric Punch System Specifications

Servo Motor + Crank System

• Maintenance-free oil-free, long service life

• Low energy consumption, minimum 40% power saving

• Problem-free long service life with less mechanical parts thanks to its unique design

• Speeds and low, medium, top punching positions can be programmed as

• All positioning actions are more precise since Servo-Electric hammer system is driven with servo motor

• Provides always maximum torque even at high and low speeds tools

• Motor integrated thermal protection and water cooling system

• Environment friendly because no oil is used

• 2 model with 20 or 30 tons punching power

• IP65 protection grade

Technical data ETP-S

| Units | ETP-S 1500×3000 | ETP-S 1500×2500 | ETP-S 1500×2500 | ETP-S 1500×2000 | |

| MAXIMUM TONNAGE | Ton (Us Tons) | 30 (33) | 30 (33) | 20 (22) | 20 (22) |

| MAXIMUM CAPACITY (X, Y) | mm (inch) | 3000×1500 (118,1×59) | 2500 ×1500 (98,4×59) | 2500×1500 (98,4×59) | 2000×1500 (78,7×59,1) |

| STATION QTY ON TURRET | Pieces | 33 | 33 | 33 | 27 |

| MAXIMUM PUNCH DIAMETER (Sheet 1 mm (0,04″) thickness) (Single tool) | mm (inch) | Ø88,9 (3,5) | Ø88,9 (3,5) | Ø88,9 (3,5) | Ø88,9 (3,5) |

| X AXIS TRAVEL | mm (inch) | 3000 + R (118,0 + R) | 2500 + R (98,4 + R) | 2500 + R (98,4 + R) | 2000 + R (78,7 + R) |

| X AXIS SPEED | m/sec (inch/sec) | 80 (3,14) | 80 (3,14) | 80 (3,14) | 120 (4,72) |

| Y AXIS TRAVEL | m (inch) | 1500 (59,0) | 1500 (59,0) | 1500 (59,0) | 1500 (59,1) |

| Y AXIS SPEED | m/sec (inch/sec) | 80 (3,14) | 80 (3,14) | 80 (3,14) | 120 (4,72) |

| X + Y DEPENDENT SPEED | m/sec (inch/sec) | 114 (44,8) | 114 (44,8) | 114 (44,8) | 170 (66,4) |

| TURRET ROTATION SPEED | Rpm | 20 | 20 | 20 | 27 |

| AUTO INDEX ROTATION SPEED | Rpm | 65 | 65 | 65 | 65 |

| MAXIMUM PUNCH STROKE For Marking 1 mm (0,04″) Stroke | Stroke/min | 2000 | 1200 | 1200 | 1500 |

| MAXIMUM PUNCH STROKE For 1 mm step on X&Y directions | Stroke/min | 900 | 900 | 900 | 900 |

| MAXIMUM PUNCH STROKE For 25 mm step on X&Y directions | Stroke/min | 600 | 600 | 600 | 350 |

| MAX. CUTTING THICKNESS WITH FIX STATION | Mild Steel | 6,35 mm (0,25 inch) | 6,35 mm (0,25 inch) | 6,35 mm (0,25 inch) | 6,35 mm (0,25 inch) |

| Stainless steel | 3 mm (0,11 inch) | 3 mm (0,11 inch) | 3 mm (0,11 inch) | 3 mm (0,11 inch) | |

| MAX. CUTTING THICKNESS WITH AUTO INDEX STATION | Mild Steel | 4 mm (0,15 inch) | 4 mm (0,15 inch) | 4 mm (0,15 inch) | 4 mm (0,15 inch) |

| Stainless steel | 2,5 mm (0,1 inch) | 2,5 mm (0,1 inch) | 2,5 mm (0,1 inch) | 2,5 mm (0,1 inch) | |

| REPITITION ACCURACY | mm (inch) | ± 0.05 (± 0.0019) | ± 0.05 (± 0.0019) | ± 0.05 (± 0.0019) | ± 0.05 (± 0.0019) |

| POSITIONING ACCURACY | mm (inch) | ± 0,1 (± 0.0039) | ± 0,1 (± 0.0039) | ± 0,1 (± 0.0039) | ± 0,1 (± 0.0039) |

| INDEX POSITIONING ACCURACY | ° | 0.01° | 0.01° | 0.01° | 0.01° |

| MULTI TOOL CHANGE TIME | Sec. | 3 | 3 | 3 | 3 |

| MAXIMUM LOAD CAPACITY | Kg (lbs) | 225 (496,04) | 200 (441,0) | 200 (441,0) | 125 (275,6) |

| AIR PRESSURE | Bar (Psi) | 6 – 7 (87 – 101,5) | 6 – 7 (87 – 101,5) | 6 – 7 (87 – 101,5) | 6 – 7 (87 – 101,5) |

| MAXIMUM STROKE | mm (inch) | 32 (1,26) | 32 (1,26) | 32 (1,26) | 32 (1,26) |

| SHEET CLAMPING (AUTOMATIC REPOSITIONING) | Pieces | 4 | 3 | 3 | 3 |

| SHEET CLAMPING FORCE | Kg (lbs) | 1200 (2646) | 1200 (2646) | 1200 (2646) | 1200 (2646) |

| POWER SUPPLY | kW (HP) | 60 (80,5) | 60 (80,5) | 40 (53,6) | 40 (53,6) |

| AIR SUPPLY | Liters/min (Us Gallons/min) | 2,5 (0,66) | 2,5 (0,66) | 2,5 (0,66) | 2,5 (0,66) |

| LINEAR AXES | X,Y | Y1 + Y2 axis of the Ballscrew Direct Drive Fanuc Servo Motor X Axis of a rack and pinion + Reducer Fanuc Servo Motor | All axes absolute Ballscrew with Fanuc Servo Motor | All axes absolute Ballscrew with Fanuc Servo Motor | All axes absolute Ballscrew with Fanuc Servo Motor |

| INDEX AXES | Absolute with Fanuc Servo Motor+Harmonic drive reducer | Absolute with Fanuc Servo Motor+Harmonic drive reducer | Absolute with Fanuc Servo Motor+Harmonic drive reducer | Absolute with Fanuc Servo Motor+Harmonic drive reducer | |

| WORKING HEIGHT | mm (inch) | 950 (37,1) | 950 (37,1) | 950 (37,1) | 950 (37,1) |

| TABLE TYPE | BRUSHED | BRUSHED | BRUSHED | BRUSHED | |

| BRUSHED+BALL | BRUSHED+BALL | BRUSHED+BALL | BRUSHED+BALL | ||

| BALL | BALL | BALL | BALL | ||

| MACHINE LENGTH | mm (inch) | 5520 (217,3) | 5520 (217,3) | 5520 (217,3) | 5520 (217,3) |

| MACHINE WIDTH | mm (inch) | 6660 (262,2) | 5000 (196,8) | 5000 (196,8) | 4290 (168,9) |

| MACHINE HEIGHT | mm (inch) | 2220 (87,4) | 2220 (87,4) | 2220 (87,4) | 2220 (87,4) |

| WEIGHT | Kg (lbs) | 22000 (44092) | 18500 (40792) | 18500 (40792) | 16000 (35270) |

| TURRET (33 STATION) | TURRET (27 STATION) | |

| 15 Pieces A station 1/2’’ Fix 1,6-12,7 mm Diameter | 11 Pieces A station 1/2’’ Fix 1,6-12,7 mm Diameter | |

| 12 Pieces B station 1-1/4’’ Fix 12,8-31,7 mm Diameter | 10 Pieces B station 1-1/4’’ Fix 12,8-31,7 mm Diameter | |

| 2 Pieces C station 2’’ Fix 31,8-50,8 mm Diameter | 1 Pieces C station 2’’ Fix 31,8-50,8 mm Diameter | |

| 1 Pieces D station 3-1/2’’ Fix 50,9-88,9 mm Diameter | 2 Pieces D station 3-1/2’’ Fix 50,9-88,9 mm Diameter | |

| 3 Pieces D station 3-1/2’’ Index 50,9-88,9 mm Diameter | 2 Pieces B station 1-1/4’’ Index 12,8-31,7 mm Diameter | |

| 1 Pieces C station 2” Index 31,8-50,8 mm Diameter |

CONTROLLER (ERMAKSAN HMI SOFTWARE)

- GE Fanuc 31i-PB – Part Program Memory, 256 KB

- Memory C, FROM / SRAM, 16 MB / 2 MB

- CPU CARD, PENTIUM, DRAM 16 MB

- Inch/Metric Conversion – Workpiece Coordinate System

- Reader/Puncher Interface 1 – External Message

- Cutter Compensation C – Part Program Memory, 256 KB

- Registered Programs, 125

- Extended Part Program Editing

- Run Hour & Parts Count Display – Graphic Display

- Multi-Piece Machining – Multiple Tool Control

- Safety Zone Check – Clamp Zone Avoidance Function

- Safety Zone Area Expansion

- CAD/CAM software: Lantek or Metalix

STANDARD EQUIPMENT

- Ermaksan Direct Drive servo punch system

- Fanuc CNC and high precision absolute encoder, dynamic, brushless alfa series servo motors

- 3 automatic repositioning clamps and loading switches.

- Ermaksan HMI and software

- Aluminum workholder

- Tool lubricating system (Airblow).

- Free standing control panel.

- Control with foot pedal.

- Tools stuck safety system

- 1 software (Lantek or Metalix).

- 27 or 33 turret stations

- Digital oil temperature indicator.

- Software for using wheel and forming tools.

- Sheet jumping switches

- Scrap box.

- Chain protection around the machine (safety system).

OPTIONAL EQUIPMENTS

- Notching and forming tools for various dimensions and forms.

- Light barrier (for CE standard machines).

- Additional sheet holding clamps.

- Multi tools of 3,6,8 stations.

- Adaptors for various stations (B, C, D).

- Special coated tools for notching stainless materials (TIN, TICN, TICN Plus, MOVIC).

- Work chute.

- Stainless steel table with ball bearing support

Product inquiry contact

Click to see contacts

Phone: +90 224 294 75 44

Email: sales@ermaksan.com.tr

Complete product portfolio: Ermaksan