Angle roll, Profile, Section bending machines

Series 3 roll, 4 roll, 6 roll bending machines

3 ROLL SECTION BENDING MACHINES

3 roll PR Line

Precise and reliable, the PR range bends any kind of small profile. The same technology that has made MG section bending machines among the most reliable in the world is now applied to small-sized bending machines. All the low-efficiency secondary components, such as chains, belts and gears, have been replaced by a direct motorization: simple but functional concepts that have always been adopted by MG. The rolls slide on high-load linear guides with manual play recovery setting, the energy of the machine is targeted without dispersion, the force is all in the bending. The key advantage of the PR LINE is the precision and speed of the movements, ideal for high quality profile processing and a mass production per hour.

the PRE technology

• Fully electric

• Three motorized rolls

• Upper roll movement with manual control displayed with memory

• Side roll manual movement for wheelbase change according to processing

• Possibility of working both horizontally and vertically

• Manual movement lateral guides

• Standard universal roll set

Optional:

• Electric movement of the side rolls to change wheelbase according to processing

• Shaft anti-deflexion system

• Custom molds for tubes and special profiles

• NC Nexus

• CNC Touch Command: EVO 4.0 and EVO 4.0 PLUS

the PRI technology

• Completely hydraulic

• Three motorized rolls

• upper roll movement with manual control displayed with memory

• Possibility of working both horizontally and vertically

• Side guides with manual movement

• Standard universal rolls set

Optional:

• Hydraulic movement of the side rolls to change wheelbase according to processing

• Shaft anti-deflexion system

• Custom molds for tubes and special profiles

• NC Nexus

• CNC Touch Command: EVO 4.0 and EVO 4.0 PLUS

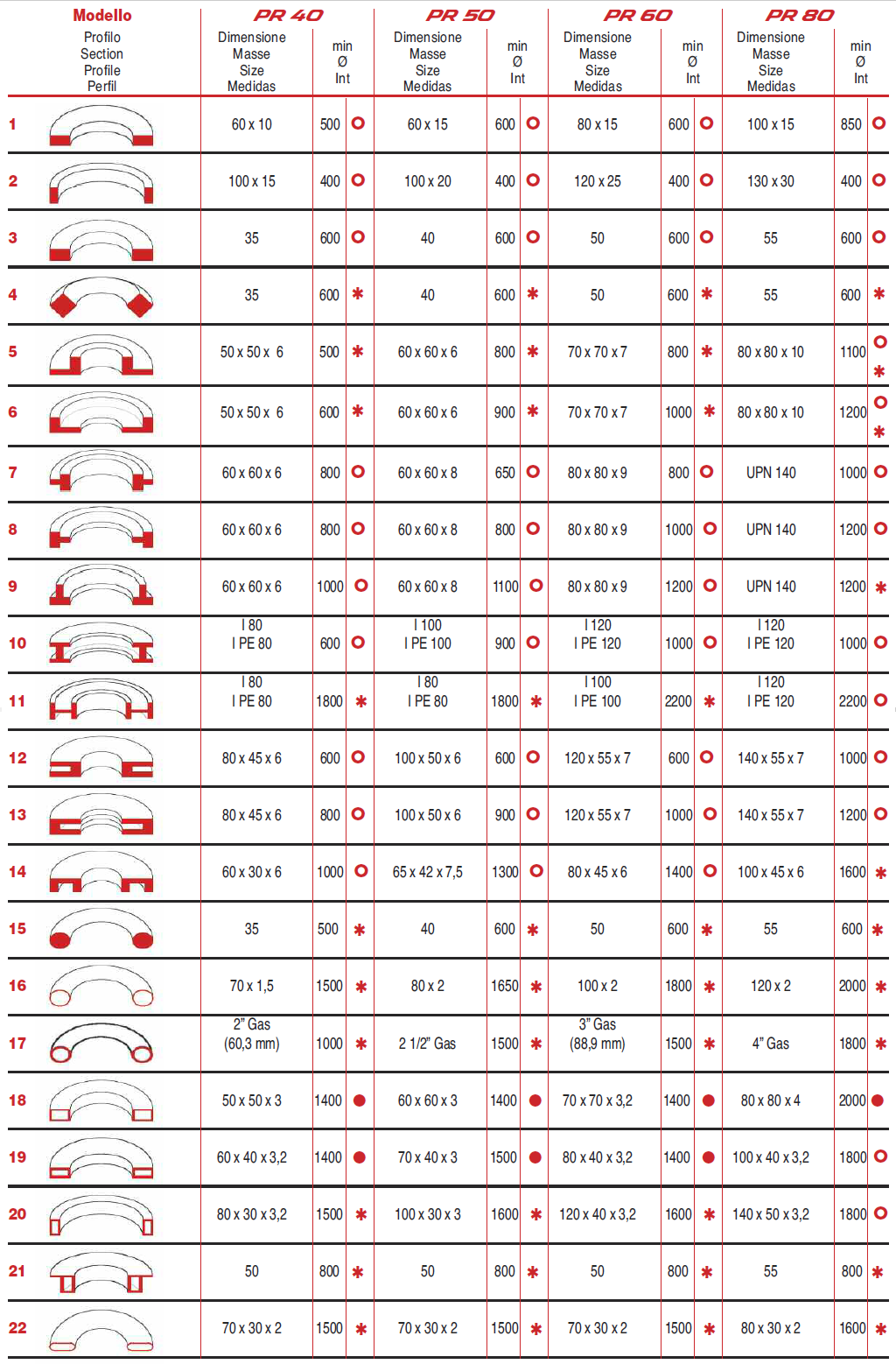

Technical data 3 roll PR Line

3 roll AR Line

They are more powerful machines, with superior capacities at a competitive price, to roll all types of profiles. Configuration of planetary movement forming rolls to minimize flat parts. The three rolls are driven by three independent hydraulic motors and three planetary gears connected directly to each roll to achieve a higher torque transmission.

Special nylon tooling can be installed when aluminum profiles are to be bent, furthermore special three-dimensional lateral hydraulic guides support and accompany the curved profile during processing.

These machines can work both vertically and horizontally.

CNC automation is possible. This MG bending machine offers the best results for bending special and standard profiles and tubes in mild steel, stainless steel, aluminum, bronze, copper and other steel alloys.

MG’s AR section rolls HT version for spiral pipes making has shorter shafts, reinforced motorisation to increase the power in order to obtain smaller diameters, side guides more powerful for better push and pitch control, in addition there is a small calibration roll in order to guarantee the pass precision, a front support with up/down and push/pull movement to give the operator a 360 degree control of the job. The aim of our engineers is to make the most of the machine accessories mechanical and hydraulic the same as if they were an extension of the operators arms but more powerful.

In ARL version the bending side rollers move on a rectilinear axis which reduces the space between the rollers themselves. In this way the pinching point of the profile between the lateral and the upper occurs in less space. The linear guides obtained by the machine structure allows to work smaller diameters with high precision, accuracy and stability. The straight part at the end of the profile is exceptionally reduced, the result is an optimal profile in all its parts.

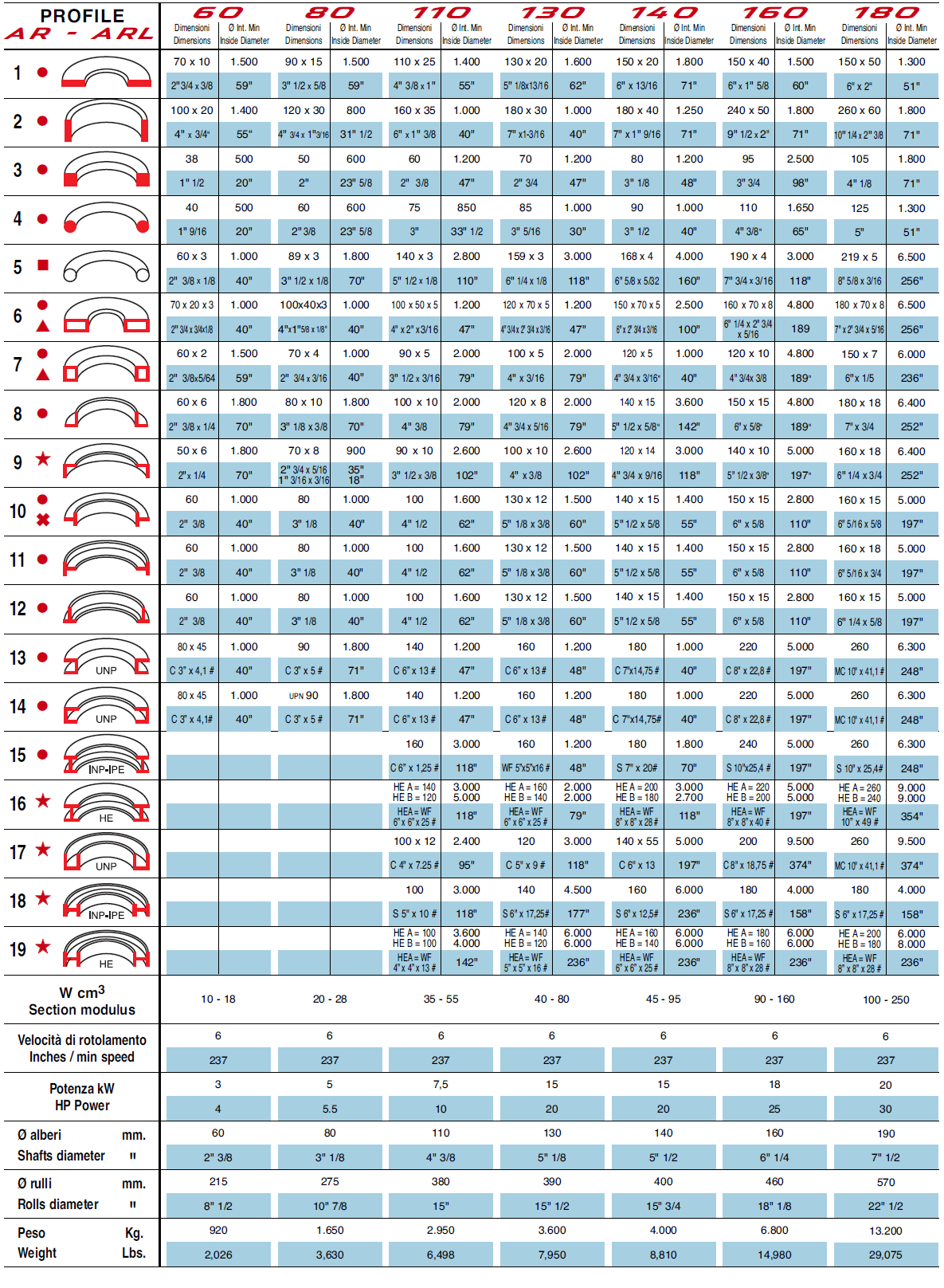

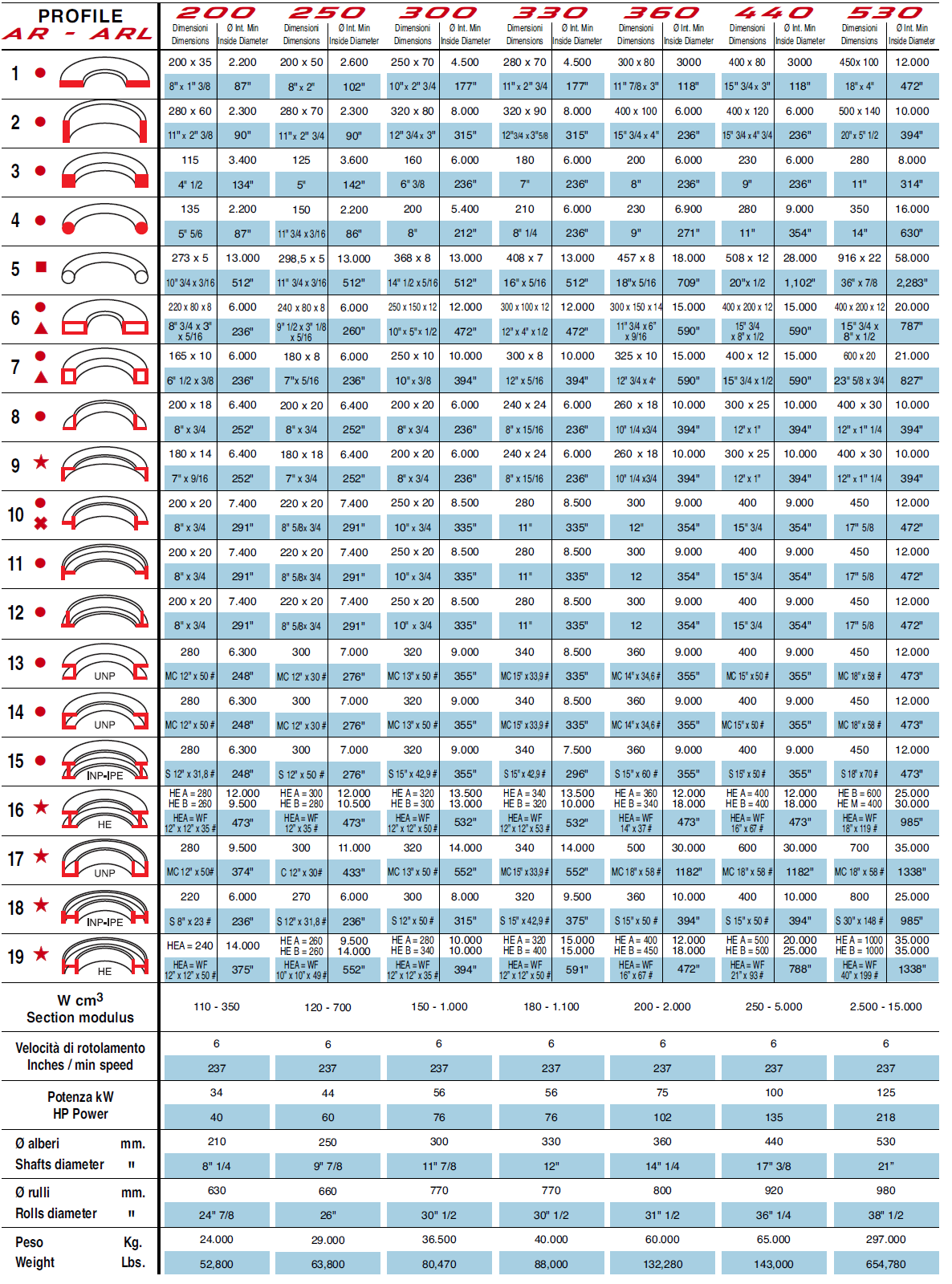

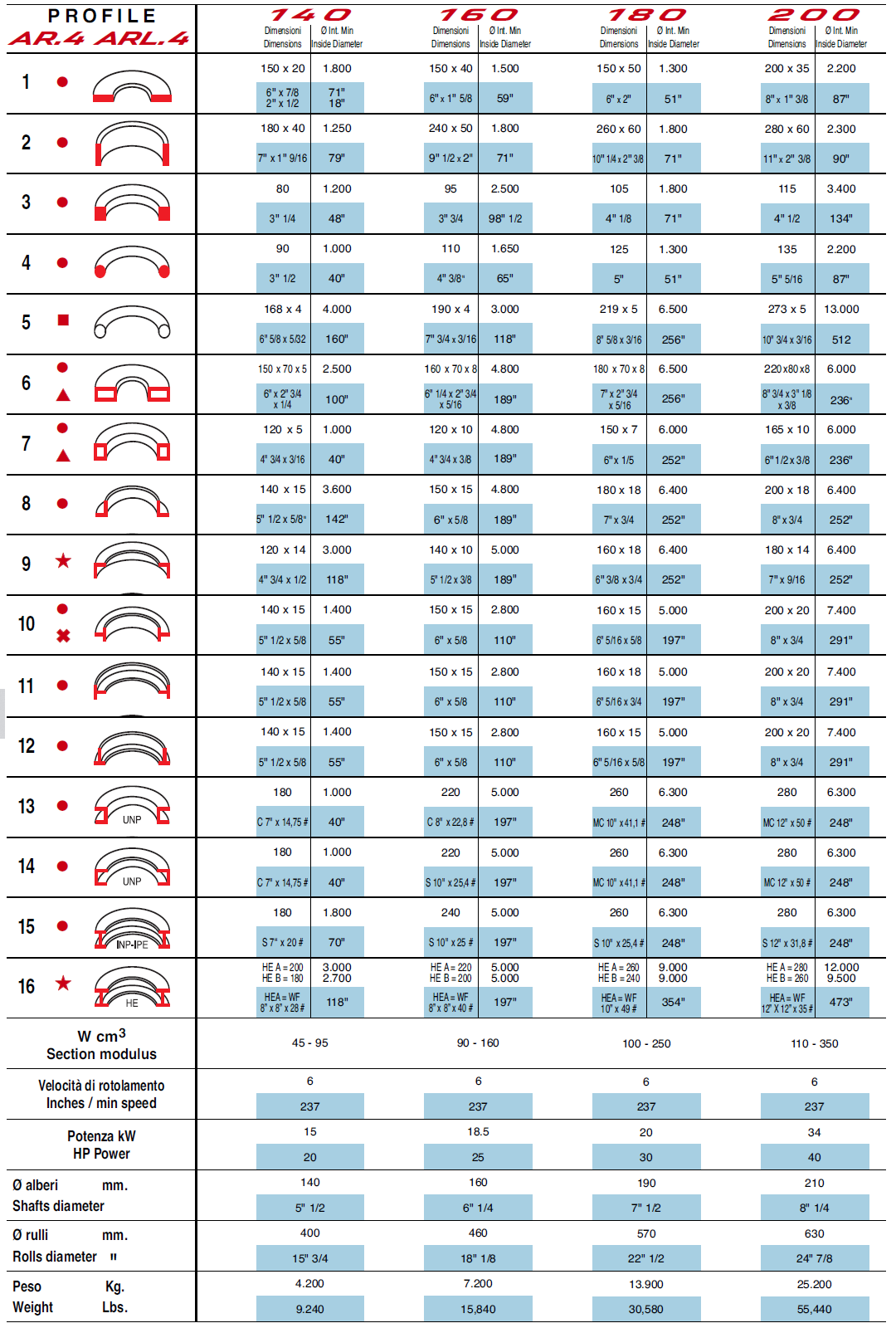

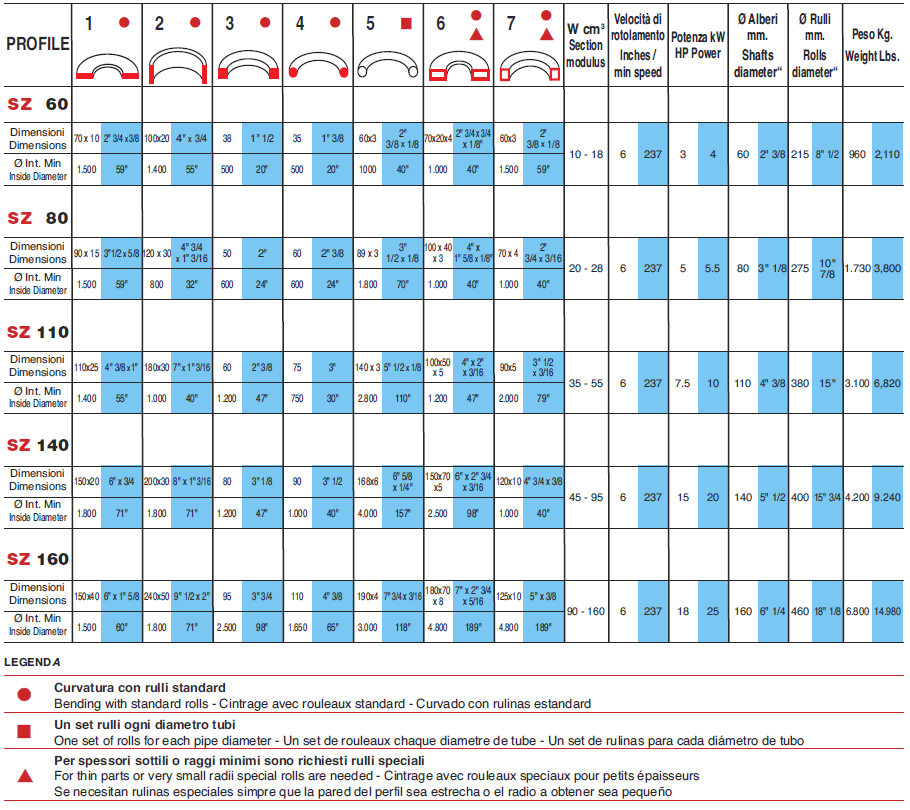

Technical data 3 roll ARL line

4 ROLL SECTION BENDING MACHINES

The 4 roll section bending machine range offers a wider distance between the side rolls allowing wider bending radiuses. Here, every secondary element is eliminated and the transmission of the torque results to be higher. The mechanical configuration of these machines also allows to minimize the flat parts at the ends of the profile.

These machines are versatile for the possibility of working both vertically and horizontally.

As per all MG machines, each component is pre-lubricated and sealed according to an exclusive system that guarantees lifetime lubrication. CNC automation is also possible on this kind of machine.

MG’s AR section rolls HT version for spiral pipes making has shorter shafts, reinforced motorisation to increase the power in order to obtain smaller diameters, side guides more powerful for better push and pitch control, in addition there is a small calibration roll in order to guarantee the pass precision, a front support with up/down and push/pull movement to give the operator a 360 degree control of the job. The aim of our engineers is to make the most of the machine accessories mechanical and hydraulic the same as if they were an extension of the operators arms but more powerful.

In ARL version the bending side rollers move on a rectilinear axis which reduces the space between the rollers themselves. In this way the pinching point of the profile between the lateral and the upper occurs in less space. The linear guides obtained by the machine structure allows to work smaller diameters with high precision, accuracy and stability. The straight part at the end of the profile is exceptionally reduced, the result is an optimal profile in all its parts.

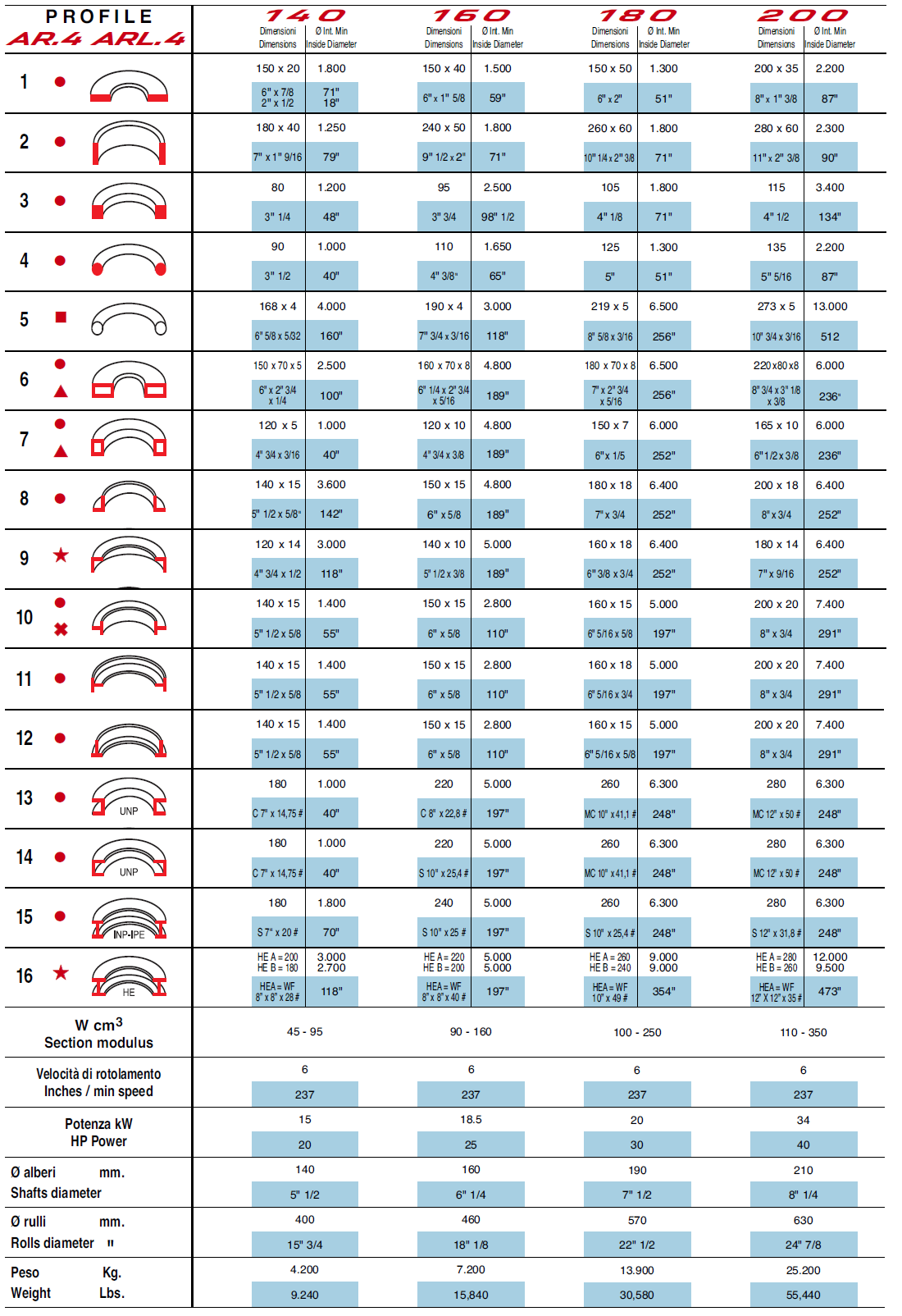

Technical data 4 ROLL SECTION BENDING MACHINES

6 ROLL SECTION BENDING MACHINES

It represents an important innovation, because it is able to bend the profile in two directions, forming an ” S ”.

It represents the last frontier of section bending machines and offers a type of curvature that the normal machines on the market cannot perform.

The bending rolls move on a vertical axis and on a linear guide system. They are also retractable, and all these features allow the special “S” processing of the profile.

This innovative machine technology allows bending empty profiles avoiding any kind of deformation. In this regard the so-called “mandrel” plays a very important role. A jointed support that, by inserting itself into the profile, accompanies the curvature while maintaining full conformity of the piece.

Technical data 6 ROLL SECTION BENDING MACHINES

For all inquiries and more info about our machines please contact us by:

Phone: +39 0172 691 327

email: info@mgsrl.com