Manual and CNC profile and section bending machines series:

MAM – Manual profile benders

MAH – Hydraulic profile benders

MAH-RIA – Hydraulic profile benders

MAH-CNC – CNC profile benders

MAH-AC – Angle bending rolls

Manual profile benders MAM

AMOB’s MAM series of manual top roll profile bending machines are an entry level to the biggest range of section benders in the world. They are extremely user-friendly and the most economical way of roll bending a wide variety of different profiles. The top roll position is manually adjusted with a linear scale for repeatability. There are also locking nuts to secure the top roll position to ensure repeatability in single pass production runs. The MAM series features both two and three driven rolls to suit every application – the three driven roll machines suit tighter radiuses and minimize material marking. The MAM series’ simplicity and reliability ensures that anyone from apprentices through to experienced workers will easily maximize the capabilities of these machines. Both horizontal and vertical working positions ensure that even in the smallest work spaces an MAM series profile bender will have its place. The MAM series is a great, cost-effective way to get into the profile bending market.

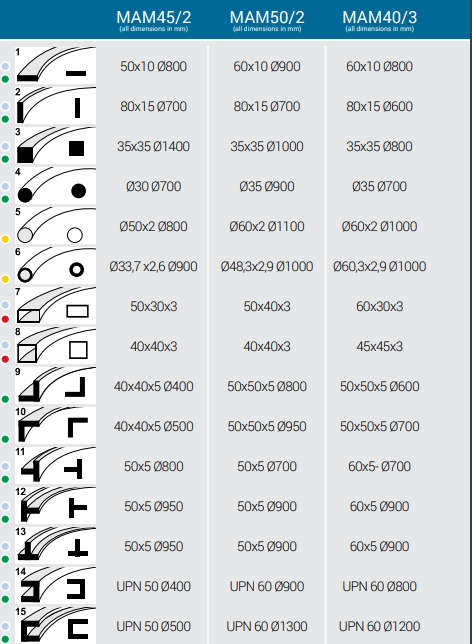

Technical data MAM

One set of rolls is required for each tube OD

Special rolls for thin wall profiles

Special rolls

| Machine model | MAM 45/2 | MAM 50/2 | MAM 40/3 |

| Section mod. | 10 cm3 | 16 cm3 | 16 cm3 |

| Power | 1,1kW – 1,5hp | 1,1kW – 1,5hp | 2,2kW – 3hp |

| RPM | 10,6/21,2 | 13,6/27,2 | 12 |

| Tool Ø | 149-79/118-59 mm | 146/98 mm | 146/98 mm |

| Shaft Ø | 30/30 mm | 50/50 mm | 45/45 mm |

| Weight | 250 kg | 290 kg | 450 kg |

| Dimensions | 660x760x1420 mm | 950x730x1420 mm | 1220x640x1440 mm |

Hydraulic profile benders MAH

AMOB’s MAH series of hydraulic top roll profile bending machines are the backbone of the biggest selection of roll

benders in the world. Extremely user-friendly, again they are completely accessible for apprentices and experienced

operatives alike. The top roll position is displayed on the DRO, based within the free standing operator control unit. The

MAH series is perfect for those applications that require multiple passes, where repeatability is key. Available in two

and three driven roll these machines can cater for the largest range of profiles in the market place. The three driven roll

machines suit tighter radiuses and minimize material marking. Both horizontal and vertical working positions ensure

that even in the smallest work spaces an MAH series profile bender will have its place. The MAH series is a perfect

compromise between capacity, repeatability, ease of use and reduction in production cycle times.

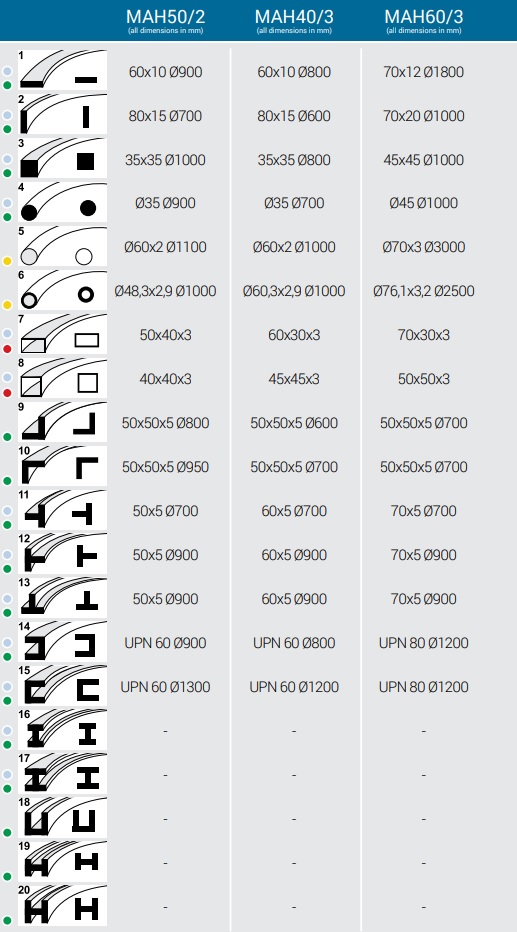

Technical data MAH

One set of rolls is required for each tube OD

Special rolls for thin wall profiles

Special rolls

| Machine model | MAH 50/2 | MAH 40/3 | MAH 60/3 |

| Section mod. | 16 cm3 | 16 cm3 | 20 cm3 |

| Power | 2,6kW – 3,5hp | 3,7kW – 5hp | 5,5kW – 7hp |

| RPM | 13,6/27,2 | 12 | 11 |

| Tool Ø | 146/98 mm | 146/98 mm | 170/108 mm |

| Shaft Ø | 50/50 mm | 45/45 mm | 55/55 mm |

| Weight | 330 kg | 490 kg | 600 kg |

| Dimensions | 940x750x1400 mm | 1200x770x1400 mm | 1300x890x1550 mm |

Hydraulic profile benders MAH-RIA

AMOB’s MAH-RIA series of hydraulic top roll profile bending machines with adjustable bottom rolls are the next step up. The adjustable bottom rolls allow both a tight radius with reduced capacity and a large radius with increased capacity – the best of both worlds. Plus, by adjusting the position of the bottom rolls you can reduce deformation along with reduced flats, and therefore waste. These additional features remain extremely user-friendly, and we’d recommend these machines for use by both apprentices and experienced operatives alike. The top roll position is displayed on the DRO, based within the free standing operator control unit. The MAH series is perfect for those applications that require multiple passes, where repeatability is key. Available in three driven rolls, these machines can cater for the largest range of profiles in the market place – again, the three driven roll machines suit tighter radiuses and minimize material marking. Both horizontal and vertical working positions ensure that even in the smallest work spaces an MAH-RIA series profile bender will have its place. The MAH-RIA series is the perfect compromise between capacity, repeatability, ease of use and reduction in production cycle times.

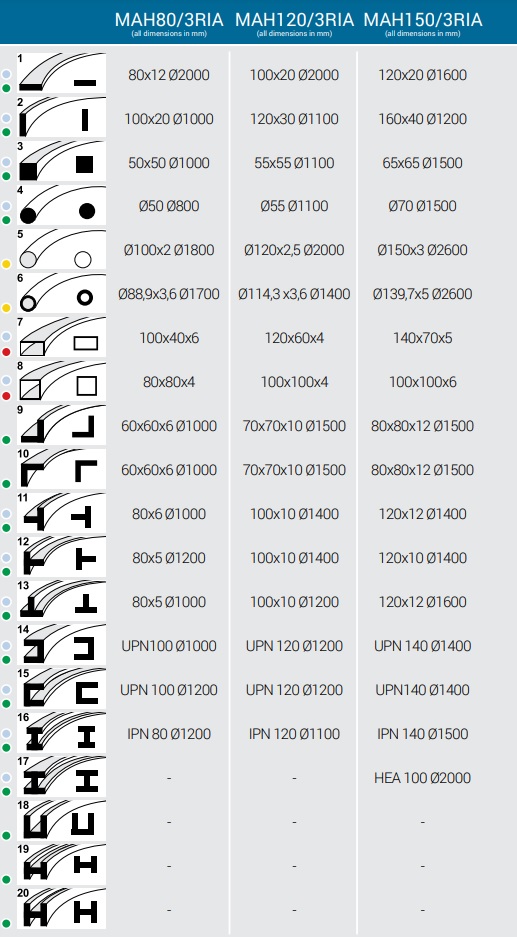

Technical data MAH-RIA

One set of rolls is required for each tube OD

Special rolls for thin wall profiles

Special rolls

| Machine model | MAH 80/3 RIA | MAH 120/3 RIA | MAH 150/3 RIA |

| Section mod. | 25 cm3 | 45 cm3 | 60 cm3 |

| Power | 5,5kW – 7hp | 7,5kW – 10hp | 10kW -13,5 hp |

| RPM | 10 | 7 | 6 |

| Tool Ø | 187/118 mm | 247/138 mm | 300/188 mm |

| Shaft Ø | 65/65 mm | 80/80 mm | 100/100 mm |

| Weight | 770 kg | 1480 kg | 2150 kg |

| Dimensions | 1520x1080x1650 mm | 1615x1260x1760 mm | 1900x1400x1850 mm |

CNC profile benders MAH-CNC

The MAH-CNC range from AMOB provides outstanding production cycle times, un-matched reliability and the production of products not possible on lower level machines. These are the first machines in AMOB’s profile section range that are fully computer-controlled. This technology allows for producing elliptical shapes on a large scale with unbeatable repeatability – plus, the MAH-CNC range is able to put multiple radiuses into a single profile using both progressive and direct pressure, opening up a new sector for product manufacture. The user-friendly 2D CNC controls make this series a popular choice for profile bending sub contractors and aluminium window and door producers, along with greenhouse manufacturers and other similar industries. The MAH CNC series takes profile bending to the next level and allows the production of products that is just not possible on MAH and MAM series machines.

Angle bending rolls

The MAH-AC series carries the largest capacity profile bending machines in the world. With planetary moving bottom rolls, they can achieve faster, tighter bending with fewer passes, which results in reduced cycle times. This range is available in both CNC and NC with AMOB’s specially developed auto learning software, which removes the need to do sacrificial test bends and therefore reduces scrap material and wasted production time. If bending the largest profiles is a requirement then look no further than the MAH-AC series from AMOB.

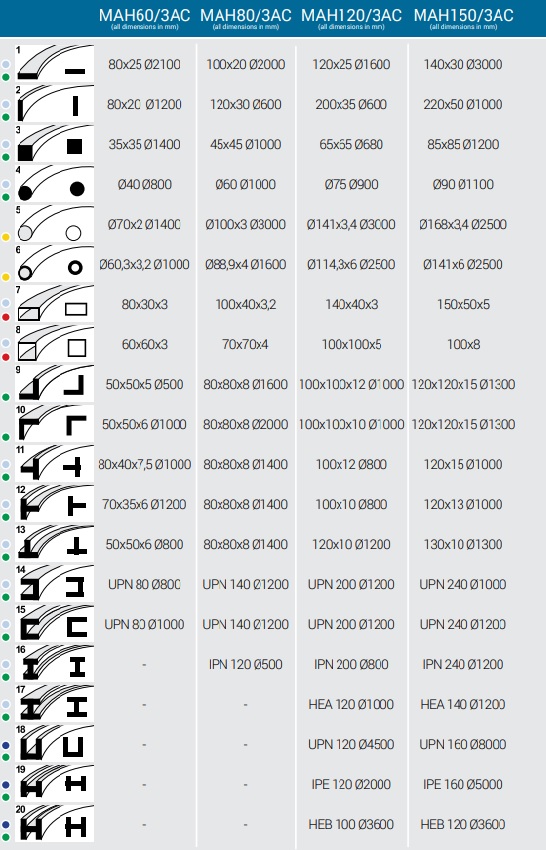

Technical data MAH-AC

One set of rolls is required for each tube OD

Special rolls for thin wall profiles

Special rolls

| Machine model | MAH60/3AC | MAH80/3AC | MAH120/3AC | MAH150/3AC |

| Section mod. | 28 cm3 | 35 cm3 | 40-80 cm3 | 80-150 cm3 |

| Power | 5,5kW – 7hp | 7kW – 9hp | 11kW -15 hp | 15kw – 20 hp |

| RPM | 11,5 | 5,5 | 5,5 | 3,6 |

| Tool Ø | 178 mm | 245 mm | 315 mm | 390 mm |

| Shaft Ø | 65/65 mm | 80/80 mm | 100/100 mm | 120/120 mm |

| Weight | 1200 kg | 1660 kg | 2800 kg | 5300 kg |

| Dimensions | 1280x1170x1445 mm | 1410x1380x1615 mm | 1435x1470x1760 mm | 2000x1815x2070 mm |

For all inquiries and more info about AMOB machines please contact us by:

Phone: (+351) 252 330 900

email: sales@amob.pt