Plasma-WaterJet combo machines with working sizes from 1000 x 1000mm up to 6000 x 12000 mm

Machine Characteristics

Patented Opal Waterjet Combo is able to combine the advantages of quick plasma cutting with precision of water jet.

Synergistic effect of combining two different technologies allows the cutting machine to exploit both assets. The cutting machine offers versatility and flexibility for a wide range of users form small to big companies.

Plasma cutting

The plasma is sufficiently hot to melt the metal being cut and moves sufficiently fast to blow molten metal away from the cut. This technology can be use to cut all metals, because they are electrically conductive.

3D water cutting

Water cutting is separating the material with a jet of water is the most accurate method for cutting and chamfering almost any kind of material. Water cutting provides the highest quality of edges and lack of heat affected zone.

Parameters of single element cutting

| Water cutting | |

| Water cutting time | 4 minutes 2 seconds |

| Water cutting speed | 253 mm/min |

| Water consumption | 15 dm3 |

| Abrasive consumption | 1,7 kg |

| Equipment | Nozzle 0,35 mm Tube 1,02 mm Accustream DiaLine Head UHDE HPS4037 Pump |

| Total cutting time | 4 minutes 2 seconds |

| Combo cutting (plasma + water) | |

| Water cutting time | 2 minutes 3 seconds |

| Water cutting speed | 253 mm/min |

| Water consumption | 9 dm3 |

| Abrasive consumption | 1,0 kg |

| Equipment | Nozzle 0,35 mm Tube 1,02 mm Accustream DiaLine Head UHDE HPS4037 Pump |

| Plasma cutting time | 18 seconds |

| Plasma cutting speed | 2020 mm/min |

| Power | 100A |

| Gas | N2/H2O |

| Plasma source | Victor UltraCut 200XT |

| Total cutting time | 2 minutes 21 seconds |

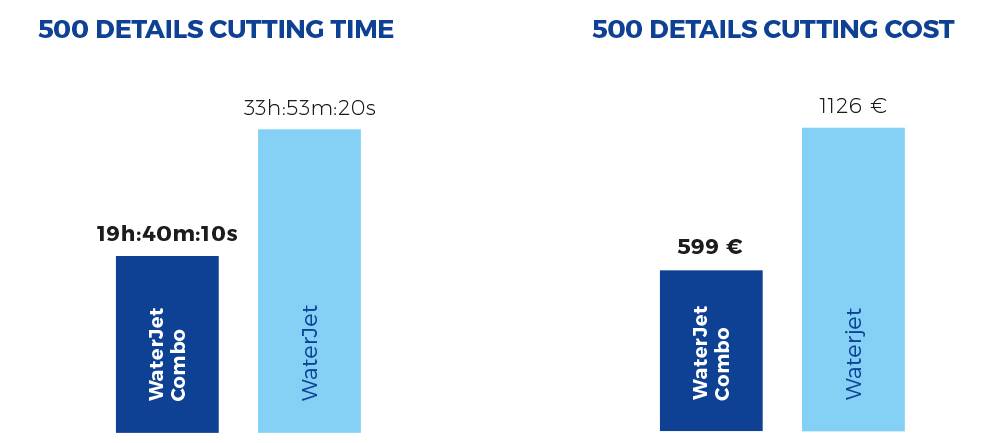

500 elements nesting. Aluminum 8 mm. Sheet 3000×1500 mm

Main Features

- innovative, patent protected technology of integrating waterjet and plasma allows automatic cutting utilizing both of them

- fully automated cutting process with two different cutting technologies

- the reduction of production costs even by 70% with comparison to standard waterjet machines

- universal cutting tool for every material

- possibility of installing Pro-X 3D head

- ability to apply any required technology during edge cutting of a single element

- robust construction and reliability

Technical data

| Model | Opal WaterJet |

| Drives | Servo AC |

| Cutting width | 1000 – 6000 mm |

| Basic working length | 1000 – 12000 mm |

| Cutting thickness – Waterjet 2D | 0,5 – 250 mm |

| Cutting thickness – Waterjet 3D | 0,5 – 150 mm |

| Cutting thickness – Plasma | Depends on the offered plasma source |

| Positioning speed | 25000 mm/min |

| Positioning accuracy | ±0,025 mm |

Standard plasma power supplies

| Kjellberg | Max. piercing | Max. from the edge |

| SmartFocus 300 | 40 mm | 80 mm |

| SmartFocus 400 | 50 mm | 100 mm |

| HiFocus 161i Neo | 30 mm | 50 mm |

| HiFocus 280i Neo | 40 mm | 70 mm |

| HiFocus 360i Neo | 50 mm | 80 mm |

| HiFocus 440i Neo | 50 mm | 120 mm |

| Q1500 | 30 mm | 60 mm |

| Q3000 | 40 mm | 80 mm |

| Hypertherm | Max. piercing | Max. from the edge |

| XPR 300 | 50 mm | 80 mm |

Standard high pressure pumps

| BFT | ECOTRON 40.22 | ECOTRON 40.30 | ECOTRON 40.30 | SERVOTRON 40.37 | SERVOTRON 40.45+ |

| Power [kW] | 22 | 30 | 37 | 37 | 45 |

| Max. flow [l/min] | 2,3 | 3,1 | 3,8 | 3,8 | 4,6 |

| Pressure [bar] | 4000 | 4000 | 4000 | 4000 | 4000 |

| KMT | TL-I 30 | NL-I 40 | JL-I 50 | SL-VI 30 PLUS | SL-VI 50 STD | SL-VI 60 PRO-III |

| Power [kW] | 22 | 29 | 37 | 22 | 37 | 45 |

| Max flow.[l/min] | 3,1 | 2,7 | 3,8 | 2,6 | 4,3 | 6,0 |

| Pressure [bar] | 3800 | 3800 | 3800 | 4136 | 3800 | 6200 |

| UHDE ThyssenKrupp | HPS 4022 | HPS 4037 HPD 4037 | HPD 4055 | HPD 4075 | HPS 6045 HPD 6045 | HPD 6090 |

| Power [kW] | 22 | 37 | 55 | 75 | 45 | 90 |

| Max. flow [l/min] | 2,3 | 3,8 | 5,7 | 7,6 | 2,8 | 5,4 |

| Pressure [bar] | 3800 | 3800 | 3800 | 3800 | 6000 | 6000 |

For all inquiries and more info about our machines please contact us by:

Phone: +48 606 676 517

email: handlowy@eckert.com.pl