CNC lathes in several models with

Turning diameter from 320 mm to 1020 mm,

Turning lengths from 720 mm to 8000 mm

Most important features:

- Ideal machine for a user switching from conventional to CNC controlled machine

- Minimal built-up area

- Easy and comfortable control

- Long lifetime with focus on keeping high machining accuracy

- Spindle drive through belts – minimization of vibration level that could negatively influence turning

- Automatic gear shifting during the working cycle

- Bearings with lifetime grease filling – low operating costs

- Annealed machine components for internal stress removal – high accuracy and stability throughout lifetime of the machine

- Machine covers with reinforced areas – high level of operator protection

CHARACTERISTIC FEATURES:

- Apron guideways with layer of friction substance – reaching positional accuracy even at minimal feed

- Preloaded ground ball screws – high dimensional accuracy of workpieces

- Machine geometry measuring by laser device – exact setting of machine axis parameters

- Variability of selection of optional turrets

- Constant cutting speed – high quality of turned surfaces

- Variety of control systems

These machines combine advantages of conventional and CNC lathes. The machine works as a conventional lathe, in manual mode, being controlled by the hand wheels. If required, the operation mode can be shifted to the full CNC control. Technological operations of machining can be programmed by simple filling-in the pre-defined cycles or eventually by standard programming. Machines are therefore suitable for piece and small-series production of simple as well as complex shapes of the workpieces from metal and plastic. Geometric accuracy of the machines fulfills norms ISO 1708 and ISO 230-1.

MAIN ADVANTAGES:

- Ideal machine for a user switching from conventional to CNC controlled lathe

- Easy operation

- Manual, cycle and automatic mode

- Software support for contour programming as well as DIN programming

- Axis positioning through servomotors

- Control system options – SIEMENS, FANUC, HEIDENHAIN

- Option of 8-positional turret with/without live tools

- Wide scope of executions and accessories – hydraulic clamping, chip conveyors, drilling bar holders, steady and follow rests, faceplates and chucks, hydraulic tailstock

| Machine type | Unit | SE320 NUMERIC | SE520 NUMERIC | SE820 NUMERIC | SE1020 NUMERIC | SE520 SL NUMERIC |

| Working Range | ||||||

| Max. swing over bed | mm | 320 | 520 | 520 | 800 | 1020 |

| Max. swing over cross slide | mm | 170 | 290 | 290 | 515 | 740 |

| Max. turned diameter with MultiSuisse toolpost | mm | B 320 | B 526/ C 476 | C 825 | C 1040 | |

| Max. turned diamerer with turret SAUTER | mm | 210 | 310 | 665 | 965 | |

| Distance between centers | mm | 750 | 950/1450* | 2000 | 2000/3000*/ 4000*/6000*/ 8000* | 2000/3000*/ 4000*/6000*/ 8000* |

| Height of centers | mm | 150 | 250 | 250 | 394 | 509 |

| Max. bar diameter | mm | 41/55* | 75/103* | 75/103* | 130 | 130 |

| Bed width | mm | 300 | 360 | 550 | 550 | |

| Main spindle | ||||||

| Spindle nose DIN (ISO702-III) | B5/B6* | B8/B11* | B8/B11* | |||

| Spindle nose Camlock (ISO702-II) | D6* | D8*/D11* | D8*/D11* | D11* | D11* | |

| Spindle nose A2 (ISO702-I) | A2-11 | A2-11 | ||||

| Spindle bore | mm | 42/57* | 77/105* | 77/105* | 133 | 133 |

| Spindle diameter in front bearing | mm | 70/90* | 120/150* | 120/150* | 180 | 180 |

| Max. spindle speed – 1st gear | min -1 | 880 | 650 | 650 | 415 | 415 |

| Max. spindle speed – 2nd gear | min -1 | 3500 | 2600 | 2600/2200* | 1600 | 1600 |

| Manual clamping | mm | 160/200* | 250/315* | 250/315* | 400/500* | 400/500* |

| Hydraulic clamping* | mm | – | 200* | 210 | 315/400* | 315/400* |

| Spindle drive | ||||||

| Main motor output S1 | kW | 7 | 11 | 11 | 30 | 30 |

| Main motor output S6 | kW | 10 | 15 | 15 | 45 | 45 |

| Torque – 1st gear S1 | Nm | 210 | 525 | 525 | 2982 | 2982 |

| Torque – 1st gear S6 | Nm | 285 | 715 | 715 | 4473 | 4473 |

| Torque – 2nd gear S1 | Nm | 52 | 132 | 132 | 761 | 761 |

| Torque – 2nd gear S6 | Nm | 70 | 180 | 180 | 1142 | 1142 |

| Carriages and drives | ||||||

| X-axis | ||||||

| Cross slide feed range | mm.min -1 | 1÷3000 | 1÷5000 | 1÷3000 | 1÷3000 | 1÷3000 |

| Cross-slide rapid traverse | mm.min -1 | 3000 | 6500 | 3000 | 5000 | 5000 |

| Working travel | mm | 183 | 270 | 270 | 405/550* | 550 |

| Z-axis | ||||||

| Longitudinal slide feed range | mm.min -1 | 1÷5000 | 1÷5000 | 1÷5000 | 1÷5000 | 1÷5000 |

| Longitudinal slide rapid traverse | mm.min -1 | 10000 | 6500 | 10000 | 6000/5000* | 6000/5000* |

| Working travel | mm | 790 | 950/1450* | 2110 | 1925/2925*/ 3925*/5925*/ 7925* | 1925/2925*/ 3925*/5925*/ 7925* |

| Toolposts | ||||||

| Quick change tool post | MultiSuisse B | MultiSuisse B | MultiSuisse B* | MultiSuisse C | MultiSuisse C | |

| Max. tool size | mm | 25×25 | 25×25 | 25×25 | 32×32 | 32×32 |

| Quick change tool post | MultiSuisse C* | MultiSuisse C | MultiSuisse D* | MultiSuisse D* | ||

| Max. tool size | mm | 32×32* | 32×32 | 40×40* | 40×40* | |

| Manual tool post systems* | ||||||

| Quick change tool post | Parat RD 2* | Parat RD 2* | Parat RD 4* | Parat RD 4* | ||

| Max. tool cross-section | mm | 25×25 | 25×25 | 50×50* | 50×50* | |

| Quick change tool post | Parat RD 3* | Parat RD 3* | ||||

| Max. tool cross-section | mm | 32×32 | 32×32 | |||

| Quick change tool post | Algra TGA-R-250* | Algra TGA-R-250* | ||||

| Max. tool cross-section | mm | 25×25 | 25×25 | |||

| Quick change tool post | Algra TGA-R-300* | Algra TGA-R-300* | ||||

| Max. tool cross-section | mm | 32×32 | 32×32 | |||

| Quick change rotating tool holder Coromant Capto | Capto C4/Multifix C* | |||||

| Max. tool cross-section | mm | 32×32 | ||||

| Quick change rotating tool holder Coromant Capto | Capto C4/Multifix C* | |||||

| Max. tool cross-section | mm | 32×32 | ||||

| Automatic turrets* | ||||||

| 4-way turret without live tools* | SAUTER* | SAUTER* | ||||

| No. of tool positions (DIN 69881) | 4* | 4* | ||||

| Max. tool diameter | mm | 80* | 80* | |||

| Max. tool cross-section | mm | 32×32* | 32×32* | |||

| Axial turret without live tools* | SAUTER* | SAUTER* | SAUTER* | SAUTER* | SAUTER* | |

| No. of tool positions | 8* | 8* | 8* | 8* | 8* | |

| Tool shank diameter (according to DIN 69880) | mm | 20* | 30* | 30* | 50* | 50* |

| Max. tool cross-section | mm | 16×12* | 20×16* | 20×16* | 32×25* | 32×25* |

| Axial turret with live tools* | SAUTER* | SAUTER* | SAUTER* | SAUTER* | ||

| No. of tool positions | 8* | 8* | 8* | 8* | ||

| No. of driven tool positions | 8* | 8* | 8* | 8* | ||

| Tool shank diameter (according to DIN 69880) | mm | 30* | 30* | 50* | 50* | |

| Max. tool cross-section | mm | 20×16* | 20×16* | 32×25* | 32×25* | |

| Driven tools motor output | kW | 4,5* | 4,5* | 5,7* | 5,7* | |

| Max. torque | Nm | 20* | 20* | 35,7* | 35,7* | |

| Max. RPM | min -1 | 4000* | 4000* | 3400* | 3400* | |

| Tailstock | ||||||

| Tailstock sleeve internal taper | MORSE 4 | MORSE 5 | MORSE 5 | MORSE 6 | MORSE 6 | |

| Tailstock sleeve diameter | mm | 60 | 80 | 80 | 120 | 120 |

| Tailstock sleeve travel | mm | 120 | 160 | 160 | 210 | 210 |

| Tailstock travel | mm | |||||

| Tailstock control | manual | manual | manual | manual | manual | |

| Clamping force range* (optional hydraulic tailstock sleeve travel) | daN | 80-800* | 80-800* | 300/2500 | 300/2500 | |

| Machine dimensions | ||||||

| Height | mm | 1735 | 1800 | 1800 | 2115 | 2115 |

| Width | mm | 1490 | 1560 | 1850 | 2325 | 2325 |

| Length (with chip pan) | mm | 2415 | 2790/3290* | 3930 | 4604/5632*/ 6660*/8604*/ 10604* | 4604/5632*/ 6660*/8604*/ 10604* |

| Length (with chip conveyor to the right side)* | mm | 3300* | 4110*/4610* | 5450* | 5955*/6955*/ 7955*/9955*/ 11955* | 5955*/6955*/ 7955*/9955*/ 11955* |

| Weight | ||||||

| Weight (without optional accessories) | kg | cca 1600 | cca 2700/2900* | cca3800 | cca 7000/8000*/ 9000*/10000*/ 11000* | cca 7000/8000*/ 9000*/10000*/ 11000* |

| Control systems | ||||||

| SIEMENS 840D SolutionLine + ShopTurn | yes | yes | yes | yes | yes | |

| FANUC 0iTD + Manual Guide i | yes | yes | yes | yes | yes | |

| HEIDENHAIN MANUAL Plus 620 | yes | yes | yes | yes | yes |

SE320 NUMERIC

SE320 NUMERIC is a machine designed for small to medium series production of smaller dimensions workpieces. This machine is also suitable for shops with piece production. This lathe can turn simple as well as complex shape workpieces such as flanges and shafts from metal and plastic. SE320 is also suitable as a teaching aid for vocational schools and colleges of technical major. Machine can be operated either in manual mode, by using electronic handwheels, or the technological operations can be performed in automatic mode, thanks to the modern control system. Using the automatic mode opens new possibilities in piece production and in increasing the productivity of small series production.

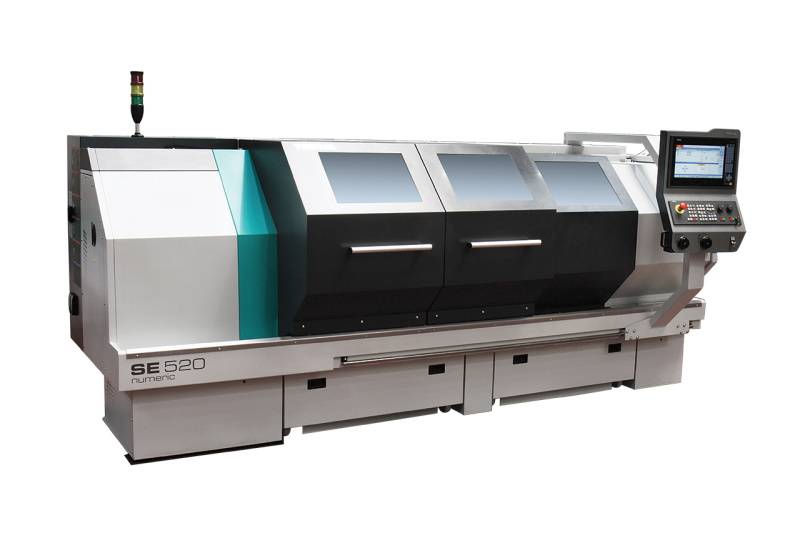

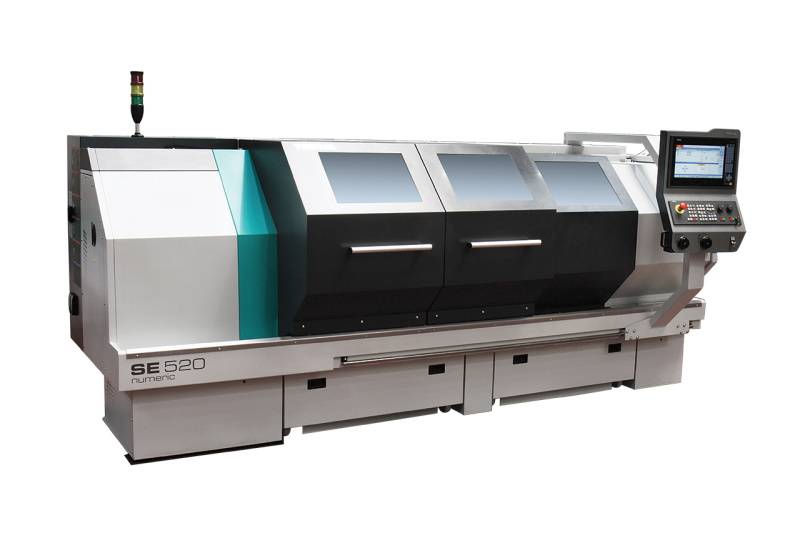

SE520 NUMERIC

SE520 NUMERIC is a machine designed for small to medium series production of smaller dimensions workpieces. This machine is also suitable for shops with piece production. This lathe can turn simple as well as complex shape workpieces such as flanges and shafts from metal and plastic. SE520 is also suitable as a teaching aid for vocational schools and colleges of technical major. Machine can be operated either in manual mode, by using electronic handwheels, or the technological operations can be performed in automatic mode, thanks to the modern control system. Using the automatic mode opens new possibilities in piece production and in increasing the productivity of small series production.

SE520 SL NUMERIC

CNC universal center lathe is designed on the basis of SE520 Numeric. Thanks to the new bed, the distance between centers was enlarged to 2000 mm. The fully covered working space allows to increase technological possibilities of long work-piece machining. The machine can turn simple, as well as complex shapes work-pieces. The machine can be customized in various optional executions and it can be equipped with various optional accessories. SE520 SL works as a universal lathe in a manual mode, being controlled by the hand wheels or in the full CNC control to perform demanding technological operations. This enables new machining possibilities for piece production and increase the productivity of small series production.

SE820 NUMERIC

SE820 NUMERIC is a machine from category CNC universal center lathe designed for turning large rotational workpieces. It allows for turning outer and inner cylindrical, conical and complex shapes and all kinds of threads as well. In combination with drilling and milling it allows machining of complex shapes from bars, forgings and split material. Wide variability in specific turning operations for gas, oil and water industries.

SE1020 NUMERIC

SE1020 NUMERIC is a machine from category CNC universal center lathe designed for turning large rotational workpieces with swing over bed up to 1020 mm. In combination with drilling and milling it allows machining of complex shapes from bars, forgings and split material. Wide variability in specific turning operations for gas, oil and water industries.

For all inquiries and more info about our machines please contact us by:

Phone: +421 915 180 451

e-mail: trens@trens.sk