WaterJet cutting machines with cutting width from 1000 to 6000 mm and cutting lenght from 1000 to 12000 mm,

Cutting thickness up to 250mm for steel, stone, wood, plastic materials

Characteristics

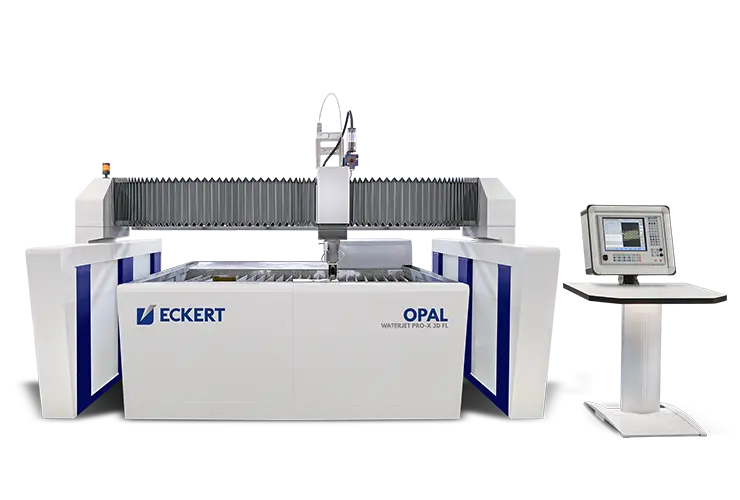

Opal Waterjet cutting machine was created in response to the need of obtaining smooth, high quality finish with no heat-affected zone or thermal distortion. Utilization of waterjet cutting allows work with a wide variety of materials such as: stone, wood, plastics etc. up to 250 mm thickness. Optional use of PRO-X 3D cutting head widens design capability of the machine by 3D operations.

Main Features

- versatility

- there are no dust as a by-product of cutting

- abrasive or pure water cutting

- waterjet cutting system can operate with up to four cutting heads at a time

- customised high pressure pump adjustment

- dross free cutting minimizes post processing

Technology

Construction

Opal Waterjet has gantry construction. The machine is made from steel closed profiles which ensure great stability. Rail elements where protected against harmful influence of water with protective bellows or covered by aluminium parts. Relatively low weight of the gantry and specially grounded racks furnishes our Opal Waterjet with excellent dynamics and high precision motors boosts accurate positioning.

ECS872 Control Panel

The most modern i-Vision Controller is the high quality industry machine has Corning® Gorilla® Glass’s touchscreen. Efficient parts and the strong construction ensures reliability Onyx working. Many functions of own software and simple controller’s interface let to use all of machine’s possibilities. Standalone controller delivers the unique comfort and safety of machines operator. It make also possible to watching the cutting process and controller’s using at the same moment.

Water Table

Opal Waterjet cutting machine is equipped with the robust water table with double grid system. Steel, fully tinned (as option) construction insures durability and corrosion resistance. The detached table construction ensures maximum stability and smooth running operations.

2D Cutting Table

2-axis waterjet cutting head Accustream is utilising proven in practice hydro-abrasive cutting technology. Well designed construction head equipped with height sensor and anti collision device guarantee the best quality cuts and faultless operation.

Technical data

| Model | Opal WaterJet |

| Drives | Servo AC |

| Cutting width | 1000 – 6000 mm |

| Basic working length | 1000 – 12000 mm |

| Cutting thickness – waterjet 2D | 0,5 – 250 mm |

| Cutting thickness – waterjet 3D | 0,5 – 150 mm |

| Positioning speed | 25000 mm/min |

| Positioning accuracy | ±0,025 mm |

Standard high pressure pumps

| BFT | ECOTRON 40.22 | ECOTRON 40.30 | ECOTRON 40.30 | SERVOTRON 40.37 | SERVOTRON 40.45+ |

| Power[kW] | 22 | 30 | 37 | 37 | 45 |

| Max. flow [l/min] | 2,3 | 3,1 | 3,8 | 3,8 | 4,6 |

| Pressure [bar] | 4000 | 4000 | 4000 | 4000 | 4000 |

| KMT | TL-I 30 | NL-I 40 | JL-I 50 | SL-VI 30 PLUS | SL-VI 50 STD | SL-VI 60 PRO-III |

| Power [kW] | 22 | 29 | 37 | 22 | 37 | 45 |

| Max. flow [l/min] | 3,1 | 2,7 | 3,8 | 2,6 | 4,3 | 6,0 |

| Pressure [bar] | 3800 | 3800 | 3800 | 4136 | 3800 | 6200 |

| UHDE ThyssenKrupp | HPS 4022 | HPS 4037 HPD 4037 | HPD 4055 | HPD 4075 | HPS 6045 HPD 6045 | HPD 6090 |

| Power [kW] | 22 | 37 | 55 | 75 | 45 | 90 |

| Max. flow [l/min] | 2,3 | 3,8 | 5,7 | 7,6 | 2,8 | 5,4 |

| Pressure [bar] | 3800 | 3800 | 3800 | 3800 | 6000 | 6000 |

Video

For all inquiries and more info about our machines please contact us by:

Phone: +48 606 676 517

email: handlowy@eckert.com.pl